Dyneo+, the new range of connected motors with very high efficiency levels

With 15 years of experience and over 3 gigawatts of installed base, Nidec Leroy-Somer is recognized as a leader in offering high energy efficiency synchronous motor and variable speed drive solutions.

Drawing on its strong expertise, Nidec Leroy-Somer have developed Dyneo+, a new range of super premium efficiency permanent magnet-assisted synchronous reluctance motors which incorporate alone all the benefits of induction and synchronous permanent magnet technologies, and offer in addition significant advances in terms of smart drive solutions.

Class leading energy efficiency

With an energy efficiency level above IE5 reaching the highest efficiency levels of IEC 60034-30-2 and NEMA Super Premium / Ultra-Premium, Dyneo+ makes it possible to achieve substantial energy savings in real use on cycle at variable speed and load. As a consequence, the range achieves the lowest Total Cost of Ownership on the market.

The Dyneo+ synchronous motor range has been developed alongside the Nidec Leroy-Somer variable speed drives, Powerdrive F300 and the new Powerdrive MD Smart. Perfectly adapted to optimize the Dyneo+ motor performance, this last generation of high power speed drives is fitted with a new HMI and a secured

Bluetooth connection to enrich the user experience and fully benefit from the features of the new Systemiz application.

Fast and easy operation thanks to digitalization

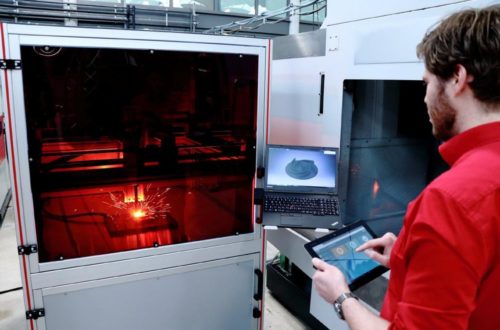

Dedicated to its Dyneo+ motors, Nidec Leroy-Somer has designed Systemiz, a unique interactive application which provides a wide variety of digitalized services, to facilitate the exchange of information between the systems and trigger the subsequent actions.

In addition to instantaneous access to all the product literature, Systemiz enables direct access to motor parameters for easy and intuitive drive setting by simply scanning the QR code on the nameplate. Thanks to the new fully configurable Powerdrive MD Smart Interface module, it is now possible to set up predictive maintenance with the help of customized alarm generation and innovative diagnostic tools.

Interactive configuration and quick setup offer a considerable cost-saving, constituting a major advantage.

Torque and speed performance

Designed for variable speed, this new range delivers optimized overall operating performance for operation with or without position feedback.

Offering accurate speed and torque control, the Dyneo+ drive and motor assembly guarantees constant torque over extended speed ranges, with no derating or forced ventilation. This is also an easy-to-implement solution, highly-effective for applications requiring high torque at high speed. High starting performance in sensorless mode avoid the need for an encoder.

Reliability and simplicity

Nidec Leroy-Somer has developed the Dyneo+ range based on the mechanical platform of its IMfinity® induction motors, known for their robustness and reliability. The use of proven components provides these new motors a great strength of design and an extended service life. Among others, these choices of construction include bearings adapted to variable speed applications and sized to withstand heavy loads on the shaft, winding with reinforced insulation, rare earth free rotor with low overheating and excellent thermal protection thanks to CTP and PT100 sensors fitted as standard.

Dyneo+ was designed to ensure fast installation, simple parameter setting and easy maintenance. Equipped with a large terminal box for easier wiring, the motor can be assembled or dismantled as simply as an induction motor. Through the technology using rotor low losses, Dyneo+ reduces maintenance costs particularly in increasing greasing intervals.

High degree of adaptability

Ranging from 11 to 430 kW for speeds up to 6000 rpm, Dyneo+ comprises two variants suitable for all kinds of configurations:

- A version 100 % interchangeable with a standard IEC motor that can be easily integrated in machines,applications or systems without any modification of the existing design.

- An extremely compact version with one of the highest power-to-weight ratio on the market, to address anyof space constraints and optimize energy consumption.

In addition to the IP55 version with aluminium housing (LSHRM range) and the IP23 steel version (PLSHRM range), Dyneo+ now proposes a cast iron range (FLSHRM) ideally suited for aggressive environments or applications exposed to severe mechanical stresses.

These advantages make Dyneo+ an extremely versatile range in full compliance with the requirements of markets in the industrial refrigeration, compression, pumping, ventilation, extrusion, grinding, etc. Dyneo+ adapts to process applications, combining energy imperatives and productivity needs.

About Leroy-Somer:

Leroy-Somer is one of the world’s leading manufacturers in electromechanical and electronic drive systems and the world leader in industrial alternators. The company was established in 1919 in France and employs around 6200 people worldwide.

Nidec was established in Kyoto, Japan in 1973 by its Chairman, President and CEO Shigenobu Nagamori. In 1979, Nidec became the first company in the world to successfully commercialize a direct drive spindle motor for HDDs based on a brushless DC motor. Since then, the Company has grown into a world-leading comprehensive motor manufacturer encompassing approximately 300 subsidiaries employing 120,000 people throughout the world and with annual sales of about US$ 14.6 billion. Nidec’s motors, drives, generators and related products are found in a diverse range of applications including computers, smartphones, home appliances, automobiles, manufacturing plants, robots and more.

Nidec Leroy-Somer Holding

Hesslingsweg 6

44309 Dortmund

Telefon: +49 (231) 9250 1015

http://www.nidec-gpm.com

MEPAX

Telefon: +34 (655) 783-193

E-Mail: e.ahossi@mepax.com

LEROY-SOMER

Telefon: +33 (5) 456444-14

Fax: +33 (5) 456444-24

E-Mail: Agnes.FERRANT@mail.nidec.com

![]()