Partial renewal of the Stuttgart Airport runway

The mammoth project was launched on April 6, 2020. Completion is scheduled for June 18, 2020 – "And we can make it," says Peter Harig, Karlsruhe Branch Manager at SAT Spezialbau GmbH. The experts for sawing and cutting technology swear by the quality of Lissmac floor saws for their often time-critical and always material-intensive projects.

No experiments with equipment

“In Stuttgart, the floor saws run 24 hours a day. The technology has to work one hundred percent. Breakdowns simply cannot occur. Lissmac stands for reliability and performance – and has been our brand of choice for years,” says Harig. There is simply no time for troubleshooting and repairs on such tightly scheduled large-scale construction sites. Only when the concrete slabs have been cut can the excavators get to work with hydraulic hammers, grabs and shovels and prepare a fresh bed for the new surface. “Everyone has to wait if we don’t keep to the schedule. That would be unthinkable. Our entire team is fully committed and uses their experience and expertise to ensure that the cutting work runs like clockwork,” says Harig. SAT Spezialbau once again strengthened its arsenal of machinery in order to start this high-pressure project and be well-equipped on all fronts. The newly acquired Lissmac UNICUT UC 520 floor cutter with side cutter and depth cutting device, together with another Lissmac UC 520 and a Lissmac MULTICUT MC 900, formed the rapid response force for Stuttgart.

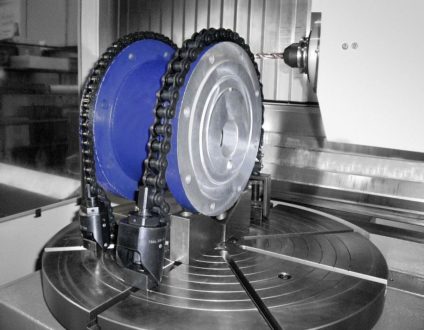

Made for serious business: the UNICUT 520

The concrete-busting network comprised a staggering 20,000 m of deliberately placed separating cuts, which the specialists from SAT Spezialbau milled into the disused runway at Stuttgart Airport in just four weeks. The cuts through concrete and iron were up to 40 cm deep. This formed the essential preparatory work to transform 1,200 m of runway into 28,000 m³ of rubble – over 1,000 trucks full to the brim. The Lissmac UC 520 — which SAT Spezialbau in Stuttgart used in a double pack — is designed for such high permanent loads during joint cutting. The joint cutter is supplied with power and endurance by a high-torque, low-vibration Deutz 4-cylinder diesel engine which delivers 74.4 kW / 101 hp. The saw blade diameter can be up to 1,500 mm. The maximum depth of cut is 630 mm. In addition to sheer power, the UC 520 also impresses with superior ergonomics and versatility. The machine offers its driver several seating position, for the best overview in every situation. Lissmac developed the intuitive operating concept with multifunctional joystick and the clear central display in collaboration with long-term users. The UC 520 masters both thrust and drag cuts. In addition, the machine can be converted very quickly from left to right-hand cutting.

Superbly adaptable with side cut device

SAT Spezialbau ordered their new Lissmac UC 520 with the optional side cut device. It is used to cut expansion joints, and especially transverse joints in fresh concrete. In order to do so, the saw blade and the blade drive can be moved along the joint cutter beyond the wheel base. This makes it possible to execute cuts right up to the edge of the road. Peter Harig is enthusiastic about the benefits of the side cutter: “The UNICUT 520 can be switched from deep cutting to fresh concrete cutting with just a few simple steps. We made extensive use of this extremely practical function in Stuttgart and, in addition to the 20,000 m of cutting in old concrete, we also made 20,000 m up to 25 cm deep of fresh concrete cuts. All with one machine, without wasting time on tedious retrofitting.”

Strong team performance

Together we are even stronger. This also applies to power packs such as the Lissmac UC 520. The tightly scheduled gargantuan task at Stuttgart would not have been possible with just a single high-performance floor saw. The experts at SAT Spezialbau, experienced in large-scale projects, planned sufficient machine output and, in addition to a second UC 520, also brought a Lissmac MULTICUT MC 900 to the airport construction site. The flagship of the MULTICUT series is available with a 55 kW / 74.8 hp Hatz 4-cylinder diesel engine that complies with the current Euro Stage V emissions standards. Thanks to its smooth axle steering, the machine can be operated by hand without a great deal of effort. There is also the option of using the MC 900 as a ride-on machine. The driver is able to control the joint cutter — which is optimized for single-handed operation — precisely and safely, even after hours of cutting operation. The low-vibration drive and the excellent straight running of the MC 900 ensures stress-free operation. “Our machine operators benefit enormously from the excellent directional stability and the overall easy operation of the Lissmac floor saws. Concentration and motivation remain high – even on this tough ride of over 20 kilometres. There were no breakdowns. We are proud of our performance. We are ready to go for the next job,” says Peter Harig.

LISSMAC Maschinenbau GmbH

Lanzstraße 4

88410 Bad Wurzach

Telefon: +49 (7564) 307-0

Telefax: +49 (7564) 307-500

http://www.lissmac.com

Telefon: +49 (7564) 307-248

Fax: +49 (7564) 307-9248

![]()