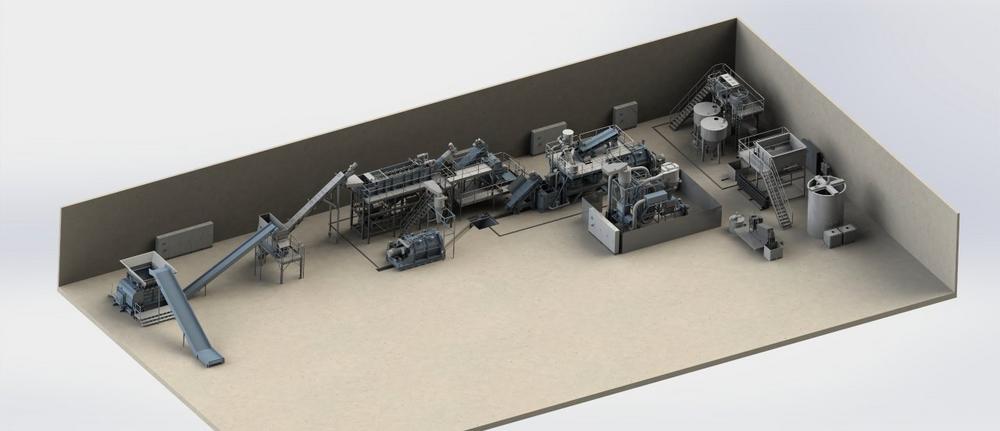

Another Herbold Washing Line in the UK

The plant is another step to cover the growing demands for high quality plastic recycling in the UK. According to its Government, an additional tax on plastic packaging is very likely to be introduced in 2022. The initial amount accounts to £200 per ton on packaging which does not include at least 30 percent recycled material. This will encourage the demand for high quality recyclate.

One of the highlights of the latest project is the HERBOLD EWS 45/200 shredder which is used as a pre-shredder prior to the wet granulator. The new concept particularly enhances the accessibility to the knives and sieves on behalf of a user-friendly handling. A gearless belt-driven propulsion system in combination with a mechanical clutch, offers additional protection against demolition caused by foreign bodies. The rotor can be equipped with variable knife configurations and as an option with easy to change armour-plating.

In order to obtain the highest quality of the final product, a hydrocyclone is used instead of a conventional separation tank which achieves higher separation levels, exerts more friction upon the material, hence generates purer flakes. These considerably better outcomes were confirmed prior to the customers´ purchase decision via tests carried out in the Herbold test center.

Herbold Meckesheim is in a good position to comply with increasing demands for high quality plastic recyclates. The latest washing plant generation makes a major contribution to more circularity in England.

Herbold Meckesheim GmbH is a leading recycling specialist for the plastics industry. The plants help worldwide to reduce and recycle plastic waste. Plants manufactured by Herbold are in are appropriate for treating "clean" waste as well as post-consumer, mixed and contaminated plastics for the plastics processing industry. The machines are used for pulverizing synthetic granules and plastic waste as well as for many other applications in waste recovery, resource recycling and material preparation for different industrial processes. Herbold, currently in the fourth generation, is managed by Karlheinz and Werner Herbold and develops and tests plants in their own technical lab. Herbold’s staff, well beyond 170, in Meckesheim and the cooperators of our international commercial agencies accompany the customized machines according to customer’s special application from conception and commissioning to the end of their operational use.

Herbold Meckesheim GmbH

Industriestrasse 33

74909 Meckesheim

Telefon: +49 (6226) 932-0

Telefax: +49 (6226) 932-495

http://www.Herbold.com

Marketing

Telefon: +49 (6226) 932-140

E-Mail: daniela.thurner@herbold.com

![]()