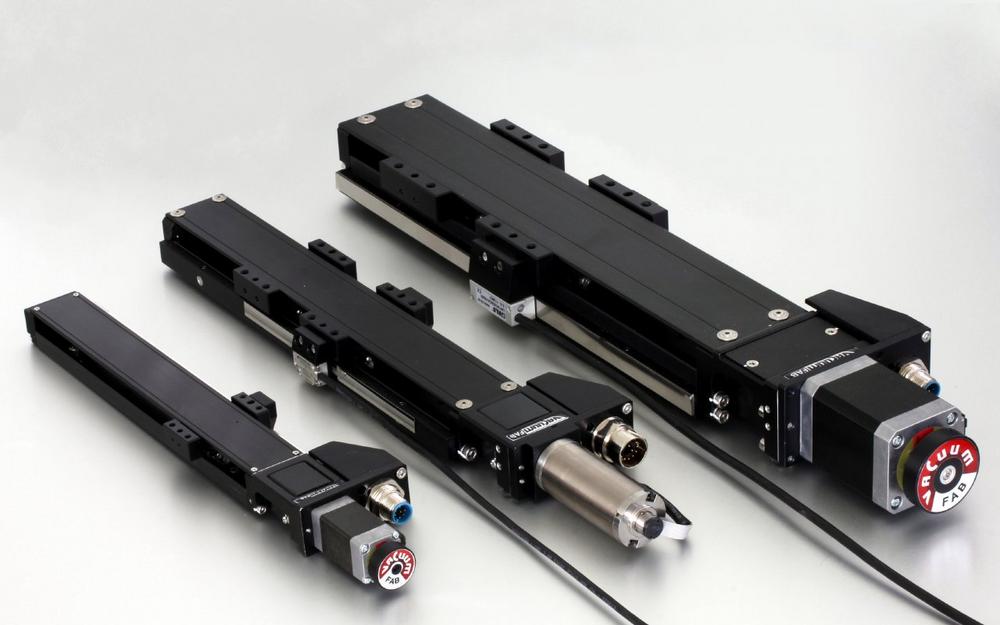

Durable, industrial class positioning mechanics: Vacuum Fab’s Hercules HLS series high-precision linear positioning stages now available from Mclennan

Vacuum-Fab s.r.l., a new sales partner for Mclennan, is an Italian designer and manufacturer of precision positioning mechanics with a high reputation for challenging extreme-environment positioning mechanics through application successes across vacuum, cryogenic and radiation settings. The Hercules HLS series is borne out of this expertise as a modular and cost-effective solution for industrial-class positioning tasks.

The Hercules HLS-S is the smallest and most compact stage in the HLS series with a nominal width of just 44 mm with a carriage width of 30 mm. With stroke lengths from 25 to 150 mm in 25 mm increments, the novel design of the HL-S offers a choice of stepper or servo motor driven leadscrews with a pitch of 2 mm for sub-micron positioning in open loop or closed loop control through a choice of servo feedback possibilities. Straightforward mounting for X-Y or X-Y-Z geometries with angle brackets and other mounting accessories are available. User adjustable end or travel limit sensors and a side mounted connector block and mating cable assemblies simplify installation.

Two other width sizes, the HLS-M and HLS-L, provide nominal widths of 52 mm and 80 mm respectively and carriage widths of approximately 40 mm and 60 mm. With precision grade leadscrew or ballscrew options that suit sub-micron positioning with stepper or servo motors, these stages feature dual-carriage options to facilitate multi-axis mounting. They are supplied complete with all mounting accessories, adjustable end of travel sensors and integral connector blocks. The available stroke is dependent on single or dual carriage set-ups with longest travel of 150 mm for the HLS–M stage and 500 mm for the HLS-L. The pre-loaded, precision linear guide bearings used across these width variants employ Gothic arch geometry for equal loading capacity from all directions. The dynamic performance, axial stiffness and load capacity can be upgraded with the double carriage option.

Across all the HLS series stage width variants, a choice of open loop or closed loop control through motor mounted rotary encoders or linear encoders is generally available. The linear magnetic or optical linear encoders provide signal outputs ranging from 1 Vpp, RS422, BiSS-C or SSI. Magnetic encoders are available as absolute or incremental, optical encoders provide incremental position feedback.

Vacuum-Fab has a wide range of alternative linear and rotary positioning stages, plus microscopy and metrology equipment. Its custom design service is available for special support mechanics, customer specified interfacing or special fixtures for third party components. For specific accuracy, resolution and repeatability specifications as well as detailed dimensional and payload information across all the numerous standard options of the Hercules HLS series, and for other information on Vacuum Fab, please visit www.mclennan.co.uk.

As a motion systems integrator with distribution partnerships with many leading drive and motion control suppliers, and with its own design and build capability, Mclennan can help integrate Vacuum Fab components – specifying complementary motor, drive and control technologies for complete systems. Visit www.mclennan.co.uk for more information.

Mclennan works closely with a small number of global motion control manufacturers and with its own inhouse design and manufacturing capability the Hampshire based motion specialist offers complete integrated mechatronics assemblies with customised mechanics, gearheads and other power train components. Motor technologies include brushed and brushless servo motors, stepper motors, small AC motors and complementary gear unit drive technologies together with motion controls for competitively priced multi-axis motion and machine control for use throughout industrial and OEM automated machine applications – contact Mclennnan at sales@mclennan.co.uk or www.mclennan.co.uk.

Mclennan Servo Supplies Ltd

Unit 1, The Royston Centre, Lynchford Road,

GU12 5PQ Surrey

Telefon: +44 (1252) 531444

Telefax: +44 (0) 8707 700699

http://www.mclennan.co.uk/contact-us

Telefon: +44 (1252) 531444

E-Mail: jon.bentley@mclennan.co.uk

MEPAX

Telefon: +44 (7748) 815-825

E-Mail: e.palmer@mepax.com

![]()