Innovation for the future: Stefan Kaufmann, Federal Innovation Commissioner for Green Hydrogen (BMBF), is gathering information about the Green Steel initiative and about the use of hydrogen at Dillinger and Saarstahl

The delegation was welcomed by Jonathan Weber, Chief Operating Officer of Dillinger and Saarstahl: “We are pleased that you’ve come here to get a first-hand look at the high innovative strength of Saarland’s steel partners – Saarstahl and Dillinger – which is making the upcoming transformation process toward the production of green steel technically possible.” A joint discussion focused on the upcoming transformation of the steel industry and the challenges this will entail. “Dillinger and Saarstahl are consistently driving the technical transformation toward the production of green steel. We want to produce steel in a carbon-neutral process and contribute in this way to climate protection,” Jonathan Weber said. “We have a plan for achieving that goal. To be able to produce green steel, the steel industry now needs investment security and binding framework conditions in order to implement the transformation process. To do this, we need a sufficient amount of green electricity and green hydrogen at affordable prices at our sites.”

Another key issue for the visit was the joint IPCEI hydrogen project, for which Dillinger and Saarstahl, together with project partners STEAG, Siemens Energy, Creos and Saarbahn, are seeking IPCEI funding from the German government.

The aim of the joint cross-border hydrogen project is to establish a green hydrogen economy in Saarland, France and Luxembourg. The various sub-projects are collectively initiating a sustainable transformation process in industry and in the mobility sector. The emission-free technologies emerging from these projects are driving structural change in the border region. As industrial customers, the Saarland steel companies Dillinger and Saarstahl are playing a key role here in the strategic development with the lighthouse project “H2Syngas”.

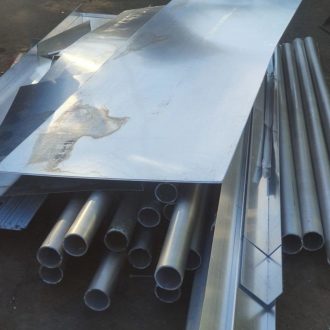

Dillinger is a world leader in the manufacture of steel heavy plate for the steel construction, machine manufacturing, offshore, offshore wind power and line pipe sectors. Saarstahl is a world leader in the manufacture of wire rod and bar steel for the automotive industry, the construction industry and for general machine manufacturing. Dillinger and Saarstahl belong to SHS – Stahl-Holding-Saar. Around 13,000 employees work under the umbrella of the SHS Group. More information can be found at www.dillinger.de or www.saarstahl.de

SHS – Stahl-Holding-Saar GmbH&Co.KGaA

Work Werkstraße 1

66763 Dillingen/Saar

Telefon: +49 (6831) 47-0

Telefax: +49 (6831) 47-4209

http://www.stahl-holding-saar.de

Leiterin Kommunikation

Telefon: +49 (6831) 47-3011

Fax: +49 (6831) 47-4209

E-Mail: ute.engel@stahl-holding-saar.de

SHS – Stahl-Holding-Saar

Telefon: +49 (6898) 10-2234

E-Mail: juliane.wernet@stahl-holding-saar.de

![]()