CERAFLOUR 1001 and CERAFLOUR 1002: sustainability par excellence

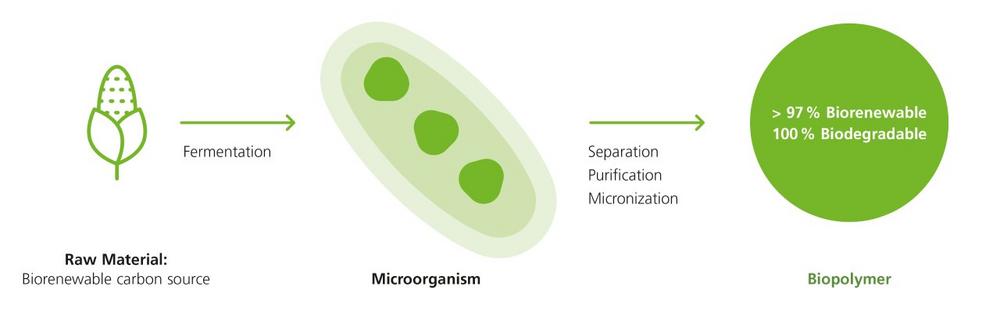

BYK recognized this trend many years ago, and began developing particularly sustainable additives. The first was CERAFLOUR 1000, a bio-based polymer that was successfully launched on the market in 2011. It has all the properties of conventional additives manufactured using either natural or synthetic waxes, but is based on > 97% renewable raw materials and is fully biodegradable.

BYK is now supplementing this successful approach with two more biopolymers that utilize the same raw material: CERAFLOUR 1001 and CERAFLOUR 1002. Both additives offer outstanding matting and surface protection in aqueous, solvent-borne, solvent-free, UV coatings and printing inks, while maintaining high transparency.

CERAFLOUR 1001 has a very fine particle size for maximum transparency whereas CERAFLOUR 1002 demonstrates the highest matting efficiency and, due to a larger particle size, enables the formation of a light surface texture.

By launching these new additives, BYK is once again supporting the coating industry in achieving its specific environmental goals.

BYK is a leading global supplier of specialty chemicals. The company’s innovative additives and differentiated solutions optimize product and material properties as well as production and application processes. Amongst other things, BYK additives improve scratch resistance and surface gloss, the mechanical strength or flow behavior of materials, and properties such as UV- and light stability or flame retardancy. In the field of quality assurance, BYK’s measuring and testing instruments serve to effectively assess appearance and physical properties.

The company’s customers include manufacturers of coatings and printing inks, plastics, adhesives and sealants, as well as cleaners, floor coatings, and lubricants. BYK additives are also successfully used in the construction chemistry, oil and gas, and foundry industries.

BYK has a global network of subsidiaries and operates production sites in Germany (Wesel, Kempen, Moosburg, Schkopau), the Netherlands (Deventer, Nijverdal), and the UK (Widnes), in the USA (Wallingford, Chester, Gonzales, Louisville, Earth City and Pompano Beach), and in China (Tongling).

The company is part of the ALTANA Group and employs a workforce of more than 2,300 people worldwide.

BYK-Chemie GmbH

Abelstraße 45

46483 Wesel

Telefon: +49 (281) 67-00

Telefax: +49 (281) 65-735

http://www.byk.com

Telefon: +49 (281) 670-25045

E-Mail: Julia.Kleist@altana.com

Leiter Kommunikation & Markenmanagement

Telefon: +49 (281) 670-25050

Fax: +49 (281) 670-75050

E-Mail: Press.BYK@altana.com

![]()