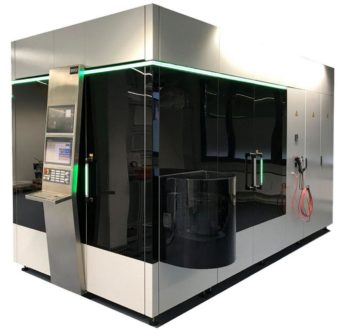

QINEO ArcBoT

The compact "Ready to weld" package is delivered completely ready for operation. This guarantees a problem-free integration into existing production processes. A torque sensor in each axis allows the Cobot to be programmed and moved precisely. The intuitive operation significantly increases work efficiency. The user can make individual adjustments on the user-friendly touch control panel with macros specially developed for welding. In addition, the Freedrive option with foot switch and the intelligent safety concept guarantee sensitive and safe control of the Cobot. Another special feature is the simple restart after an emergency stop as no extensive unlocking or free movement of the robot is necessary.

In addition to the relief of the employees – especially with monotonous, repetitive tasks – the users benefit from excellent welding results due to the consistent, reproducible quality. The integrated safety components ensure the necessary personal protection. As an option, the QINEO ArcBoT can be equipped with a torch-integrated welding fume extraction. In this case, an external extraction is not necessary.

CLOOS offers users a wide range of innovations for the economical automated welding of even small batch sizes. No matter whether the new QINEO ArcBoT, the QIROX Compact Cells, the automatic programming system QIROX RoboScan or the RoboPlan offline programming software – CLOOS supports users in finding their individual solution for welding small batches.

Since 1919, Carl Cloos Schweisstechnik GmbH has been one of the leading companies in welding technology. More than 900 employees all over the world realise production solutions in welding and robot technology for industries such as construction machinery, railway vehicles, automotive and agricultural industry. The modern CLOOS welding power sources of the QINEO series are available for a multitude of welding processes. With the QIROX robots, positioners and special purpose machines CLOOS develops and manufactures automated welding systems meeting the specific requirements of the customers. The special strength of CLOOS is the widely spread competence. Because – from the welding technology, robot mechanics and controller to positioners, software and sensors – CLOOS supplies everything from a single source.

Carl Cloos Schweißtechnik GmbH

Carl-Cloos-Straße 1

35708 Haiger

Telefon: +49 (2773) 85-0

Telefax: +49 (2773) 85-275

http://www.cloos.de

Referentin Unternehmenskommunikation

Telefon: +49 (2773) 85-478

E-Mail: stefanie.nuechtern@cloos.de

![]()