Double anniversary at the GROB in-house exhibition

When GROB hosted an in-house exhibition in Mindelheim for the first time in October 2003 twenty years ago, the family business presented its new machine concept for machining technology and impressed with its innovative technologies even then. Also celebrating this year’s anniversary is the specially developed software GROB-NET4Industry: It was developed as a worldwide novelty ten years ago and presented to the public for the first time two years later at the EMO in Milan. GROB-NET4Industry is the best proof of the enormous innovative power of GROB-WERKE.

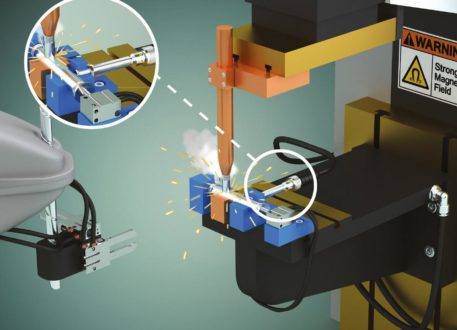

First live presentation: Hairpin bending machine

On the product side, the in-house exhibition also has a whole range of innovations to offer. For the first time in its history, GROB is presenting a hairpin bending machine to the public. It is characterized by its innovative bending concept and a high variety of variants. In the field of hairpin technology in particular, GROB has successfully evolved into the global market leader over the past seven years, as well as into a full-service provider of systems for electric powertrain production.

GROB universal machining centers can be used flexibly due to their versatile applications. At the in-house exhibition, visitors can experience this in a wide variety of machining operations that are presented live. With its individually configurable automation solutions, GROB’s product range offers the perfect solution for almost all industries in the area of 4- and 5-axis universal machining centers. Thanks to its extensive configuration options, GROB automation can be ideally adapted to the individual requirements of its customers.

Extended portfolio in the area of machining technology

In view of the transformation of the automotive industry, GROB has further expanded its product range in the area of machining technology. Examples of this development are the 2nd generation G520F of the F-series and the 5th generation G520 that will be presented without a sheet metal covering. It will offer a perfect view of the advantages of the 5-axis machine concept typical for GROB.

In-house exhibition service highlights

The range of services offered by GROB has grown disproportionately with the strong growth of the global markets and the enormous growth of the company. At the in-house exhibition, GROB will focus on five topics and explain how clients can respond to the current challenges in the market and in the economy. In addition, short technical presentations on a variety of topics will be given twice a day at the service booth, exhibits such as an interactive motorized spindle will be shown, and a special equipment box with special tools will be presented.

Digitalization – an open-ended process

At the in-house exhibition, GROB will not only celebrate the tenth anniversary of its GROB-NET4Industry software, but also present a new concept, especially on the topics of connectivity, brownfield (connection to other machine types), apps to increase productivity and digital tool data transfer. The GROB-NET4Industry products will be demonstrated live to visitors at the in-house exhibition.

Additive manufacturing – GMP300

After its successful premiere at last year’s in-house exhibition, GROB will once again present its GMP300. It is used to produce near net-shape components in the area of additive manufacturing. In addition, GROB will offer its customers the possibility of test printing as a special service. However, approval for the printing service depends on the existing capacity of the GMP300 machines at GROB. You can easily discuss further details on-site with Additive Manufacturing employees.

GROB-WERKE GmbH & Co. KG

Industriestr. 4

87719 Mindelheim

Telefon: +49 (8261) 996-0

Telefax: +49 (8261) 996-268

http://www.grob.de

Marketing, Junior Technical Marketing Managerin

Telefon: +49 (8261) 996-2089

E-Mail: emely.merkle@grob.de

![]()