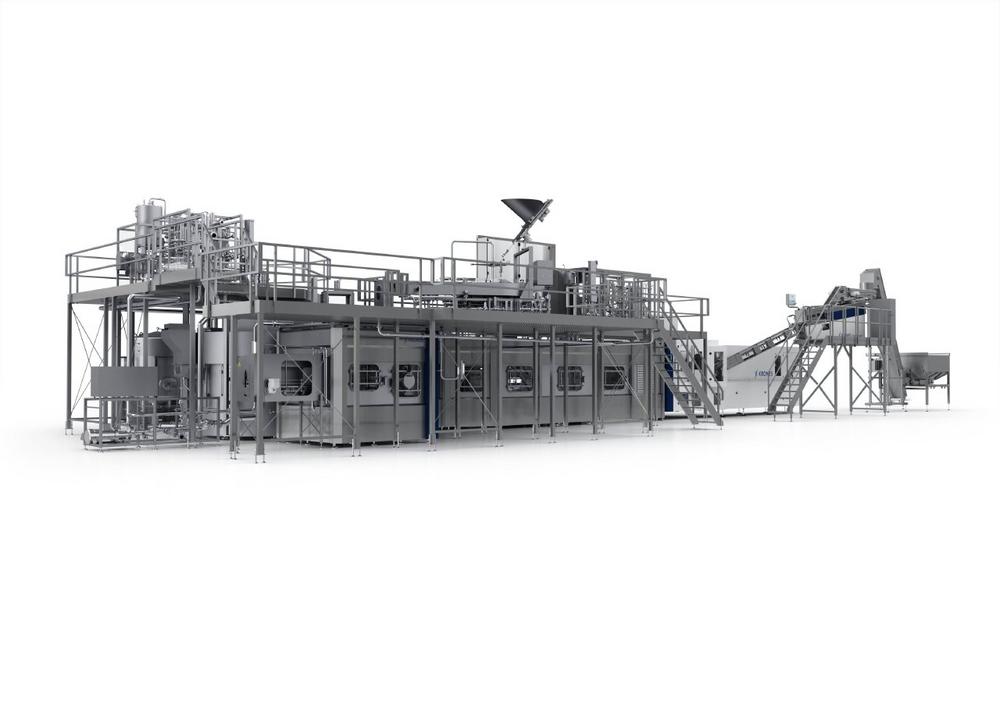

First aseptic line for Coca-Cola in India

The Coca-Cola bottler has been an innovator since the very beginning. "In 1997, for instance, we were the first bottler in the country to use PET bottles," says Anil Kumar Sharma, supply chain director for Kandhari Beverages. Krones delivered the line that made it possible, and that same equipment continues to operate reliably today. In the intervening years, a loyal, trusting relationship has developed between the two companies ¬– and Krones remains Kandhari Beverages‘ top-choice technology supplier. That held true when it came time to order a line for cold aseptic filling of sensitive beverages into sterilized containers. In this process, the product is heated only very briefly, thus ensuring minimal-to-no impact on quality and taste.

Investing in the future

Besides high product quality, this type of filling yields other important benefits. For example, it uses less energy and less material compared with hot filling. That, in turn, means lower total cost of ownership and a better ecological footprint. Wet aseptic is also extremely versatile, allowing for filling of high- and low-acid beverages alike, with or without fruit particles, fibers, or pulp. As such, the line for Kandhari Beverages is an excellent investment in the future. The line can also accommodate an expanded product portfolio at any time.

For round bottles and – for the first time – square ones, too

Kandhari Beverages uses a block for aseptic filling featuring peracetic-acid bottle sterilization and an integrated stretch blow molder. The line also provides flexibility in terms of container shape and labeling: For the first time, Kandhari Beverages is filling not only round but also square PET bottles – each in three sizes: 200 up to 1500 milliliter. Downstream, the Contiroll and Sleevematic labelers outfit the containers with wrap-around labels or sleeves, respectively.

The line is currently being installed at the company’s Jammu site, which lies in India’s northernmost union territory, which in turn borders on both Pakistan and China and is home to a burgeoning industrial center. Beginning in spring of 2023, the company will fill 36,000 PET bottles per hour for Coca-Cola – aseptically for the first time.

The Krones Group, headquartered in Neutraubling, Germany, plans, develops and manufactures machines and complete lines for the fields of process, filling and packaging technology. And Krones also offers a fit-for-purpose solution for bottle-to-bottle recycling of PET containers. The product portfolio subsumed in the House of Krones is rounded off by numerous products and services from Krones’ subsidiaries, themed around digitalisation, for example, digital container decoration, intralogistics and in-house valve production. Every day, millions of bottles, cans, and special-shaped containers are handled on lines from Krones, particularly in breweries, the soft-drinks sector and at producers of still or sparkling wines, and spirits, but also in the food and luxury-goods industries, plus the chemical, cosmetics and pharmaceutical sectors. Worldwide, Krones employs around 17,200 people. Consolidated sales in 2022 totalled 4.209 billion euros. Around 90 per cent of its products are sold abroad. The group includes not only Krones AG (listed on the stock exchange), but also more than 100 subsidiaries and further sales and service companies worldwide.

Krones AG

Böhmerwaldstr. 5

93073 Neutraubling

Telefon: +49 (9401) 700

Telefax: +49 (9401) 703323

http://www.krones.com

Press Relations

Telefon: +49 (9401) 70-5924

E-Mail: peter.moertl@krones.com

![]()