Clean All Around: High-Quality Sealing Solutions For Safe Foods And Drinks

Vegetarian, vegan, fast & slow food and much more – the range of foods and beverages is constantly evolving. There are considerable regional differences along with stringent conditions. The processing companies must react to this continuously – and the machine and equipment manufacturers must do so as well. Seal manufacturers and customers benefit from a close cooperation. “The food and beverage industry have high requirements. It really helps when the industrial companies and seal manufacturers work together closely, share their view of the market and identify trends together,” says Rainer Kreiselmaier, Technical Director for the Global Market Segment Process Industry at Freudenberg Sealing Technologies.

Seals used in the manufacture of dairy products must be resistant to fats, for example, which means to non-polar media, as well as to high sterilization temperatures. Of course, they must also comply with the specifications of an aseptic, germ-free filling technique. Beverage bottling, on the other hand, mostly involves contact with polar media that do not contain fats, as well as minimizing the transfer of aromas. In many facilities, the cleaning and sterilization are performed in a closed state to maximize the plant efficiency. However, this requires the seals to be highly resistant to the acids, alkalis and disinfection media used in this process, such as peroxides or chlorine. On top of all this, country-specific and thus very different material approvals and conformities have to be met.

For these and other challenges, Freudenberg Sealing Technologies will present various product highlights for the food & beverage industry at this year’s CibusTec trade show. It will take place in Parma, Italy, from October 24 to 27, 2023 (Hall 5, Booth 047).

Cleanliness Matters – Hygienic Product Line For Food Applications

Highest requirements for hygienic design in the food industry present major challenges for sealing technology. Thanks to special design solutions as well as premium elastomer and PTFE materials developed in-house, among others, two hygienic sealing solutions in the portfolio of Freudenberg Sealing Technologies fulfill food industry standards and are also resistant to CIP/SIP media (Cleaning in Place/Sterilization in Place). One of the basic requirements for hygienically designed sealing solutions is a construction without dead spaces. It prevents the collection and settling of product residues and micro-organisms in undercuts, for example. The selection of applied materials and their resistance to hot water, steam, acids, alkalis and high pressures are also relevant.

The Hygienic Pressure Seal from Freudenberg Sealing Technologies was designed specifically for high pressures, for example as a rod seal for use in valves or pumps. It functionally resembles a traditional rod seal, but due to its excellent performance, it also meets the high standards in hygiene. The Hygienic Forseal is based on the classic and proven forseal from Freudenberg Sealing Technologies, but its design and materials were adapted to requirements in the food industry. While the classic solution comes with a standard PTFE and a metallic tension spring, this new development uses Quantum® PTFE for its material and an elastomer ring for optimal contact pressure. Both elements form a flat and dead space free surface to the medium.

The Simmerring® Family – For Any Application in the Process Industry

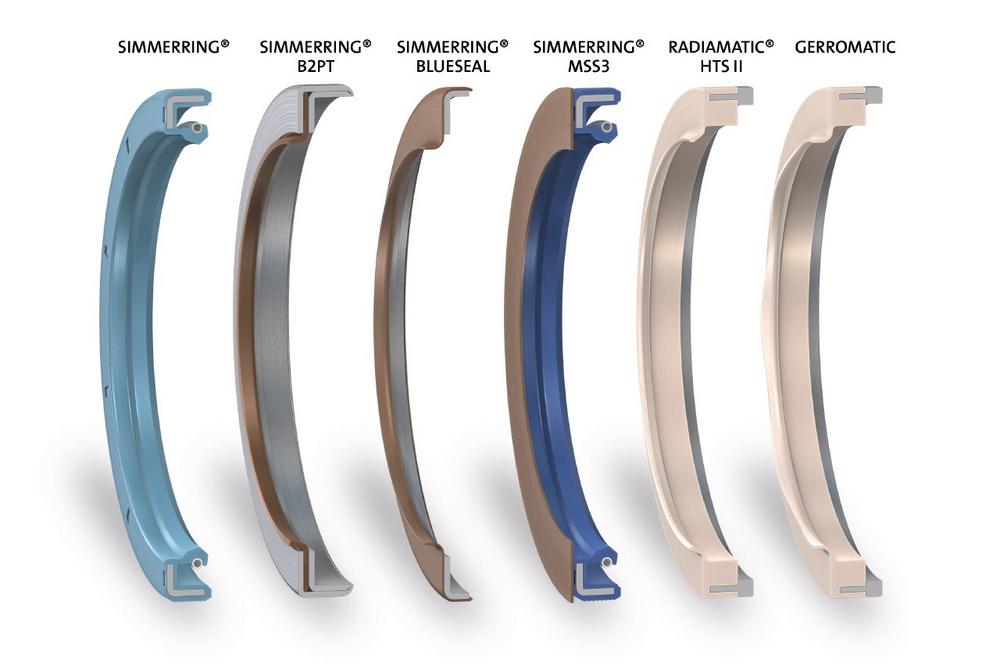

As a flexible and highly resilient solution for sealing drive shafts, the Simmerring® offers many benefits, such as high media resistance, easy adaptability to customer-specific requirements and the option to use numerous tools in standard dimensions. Freudenberg Sealing Technologies has developed an extensive portfolio of Simmerring radial shaft seals to meet the complex challenges of the food and beverage industry.

The Simmerring product family consists of various designs for the process industry, including the Simmerring BAC as a partially or fully coated radial shaft seal to meet more stringent hygiene requirements. The Simmerring MSS3 offers special protection against aggressive media and is ideal for direct contact with food products. Whenever higher pressures, extreme chemical and thermal stress, dry runs or deficient lubrication are a factor, the Simmerring B2PT is the appropriate choice. It enables stick slip-free operation and can be adapted to customer-specific requirements. The Simmerring Blue Seal is exceptionally well-suited for applications with low lubrication, high speeds, extreme temperatures and aggressive media. Additional radial shaft seals from Freudenberg Sealing Technologies, such as the Gerromatic or Radiamatic® HTS II, are made of high-performance PTFE materials combined with stainless steel clamping rings. They can easily be adapted to customer-specific installation spaces without tooling costs.

Freudenberg Sealing Technologies at CibusTec 2023

Sales and Technology experts regularly represent the company at all important trade shows, The next date: CibusTec 2023 in Parma (Italy) from October 24 to 27, 2023 (Hall 5, Booth 047).

Freudenberg Sealing Technologies is a longstanding technology expert and market leader for sophisticated and novel applications in sealing technology and electric mobility solutions worldwide. With its unique materials and technology expertise, the company is a proven supplier for demanding products and applications, as well as a development and service partner to customers in the automotive industries and in general industries. In 2022, Freudenberg Sealing Technologies generated sales of about 2.45 billion euros and employed approximately 13,500 people. More information at www.fst.com.

The company is part of the global Freudenberg Group which has four business areas: Seals and Vibration Control Technology, Nonwovens and Filtration, Household Products as well as Specialties and Others. In 2022 the Group generated sales of more than 11.7 billion euros and employed more than 51,000 associates in around 60 countries. More information is available at www.freudenberg.com.

Freudenberg FST GmbH

Höhnerweg 2 – 4

69465 Weinheim/Bergstraße

Telefon: +49 (6201) 960-6666

Telefax: +49 (6201) 88-6666

http://www.fst.com

Director, Media Relations

Telefon: +1 (734) 354-7373

E-Mail: cheryl.eberwein@fnst.com

Media Relations

Telefon: +49 (6201) 960-5709

E-Mail: christoph.klink@fst.com

![]()