One-cable hybrid connectors for greater flexibility and efficiency in plant and mechanical Engineering

One-cable hybrid connectors for greater flexibility and efficiency in plant and mechanical

Engineering | soon to be standardised in accordance with IEC 61076-2-118

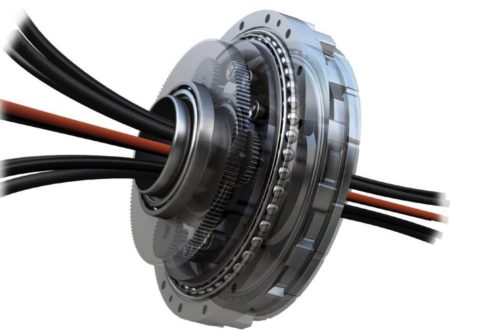

Conventional cabling of electric motors, servo drives or linear units is often very complex. Separate cables are used for power, data and signal transmission for different tasks. This wiring concept is not only expensive, but also difficult to maintain. It also takes up a lot of space. Increasing cost pressure and the miniaturisation of end devices make new solutions for more efficient cabling just as necessary as constantly increasing data volumes and high transmission speeds.

CONEC Hybrid Connectors combine power supply and data transmission in one connector.

One connector instead of two or three, shorter assembly times, no cable tangle, lower weight on the end device (e.g. motor), high modularity – these are the convincing arguments in favour of the CONEC connector series

Different sizes (B12, B17, B23, B40) for different performance classes of drives or devices offer maximum flexibility. Whether it is a small DC drive or a powerful servo drive, CONEC Hybrid Connectors provide solutions for many fields of application.

In addition, CONEC Hybrid Connectors are among the first products to comply with the future IEC 61076-2-118 standard. The standard is expected to be published at the end of 2024.

4-pole centrepiece | 3 data module variants | High modularity

The four sizes of CONEC Hybrid Connectors all have the same centrepiece: a separately shielded, 4-pin data element for transmitting Industrial Ethernet.

In addition to the 4-pole data element with Ethernet/Ethercat protocol, it is also possible to equip the data element as a blind module – for use as a pure power connector or with a 2-pole insert for 2-wire BUS protocols.

All CONEC Hybrid Connectors are locked with a bayonet quick-release fastener, eliminating the need for time-consuming tightening using a torque spanner.

In addition to the tamper-proof overmoulded connector variants as a single ended or connecting cable, all connectors are also available as field attachable variants for applications in which pre-assembled cables cannot be used.

The product range is completed by 7 different receptacle variants.

Your advantages at a glance:

- Space saving through transmission of data and power in one connector

- Modular system

- Reduced cable requirements

- Less time required for connector assembly

- Cost saving

- Quick and secure connection with bayonet lock

- Protection class IP67

- Compact and robust design

Fields of application:

- Drive technology

- Mechanical engineering

- Robotics

- Assembly and production lines

- Renewable energies

For more than 40 years, CONEC Elektronische Bauelemente GmbH has been developing, producing and marketing high-quality connectors, patch cable and single ended cable as well as enclosure technology.

CONEC products are used in automation, telecommunications and energy technology, machine manufacturing, agriculture and medical technology, transportation and the aviation industry.

The headquarters in Lippstadt has a large research and development department, its own tool-making department, a CNC-turning department and a synthetics injection moulding plant.

As part of the Amphenol Group, CONEC participates in the growth and development opportunities of a globally active group and at the same time acts flexibly and quickly as a medium-sized company in order to optimally adapt to changing customer needs.

In addition to a variety of connectors for all current standards, our particular strength is the integrated moulding of components and assemblies and the development of customized solutions.

CONEC is a global player with its own subsidiaries and/or production sites in Canada, China, the Czech Reblublic, Poland, Slovakia and Mexico.

The product portfolio includes connectors of the following categories:

• D-SUB/IP67 D-SUB Connectors

• IP67 RJ45 / USB / Mini USB / Fiber Optic LC Duplex

• CONEC Hybrid Connectors

• Connectors for agricultural and construction machines

• Circular Connectors

• PCB Connectors

• Customer specific solutions

The company’s quality management ensures high quality by applying the international standards according DIN EN ISO 9001. Depending on the product family, CONEC industrial connectors are tested and approved in accordance with UL, CSA or VDE.

CONEC Elektronische Bauelemente GmbH

Ostenfeldmark 16

59557 Lippstadt

Telefon: +49 (2941) 765-0

Telefax: +49 (2941) 765-65

http://www.conec.com

Marketing Communications Manager

Telefon: +49 (2941) 765-350

Fax: +49 (2941) 765-65

E-Mail: Katja.schade@conec.de

![]()