Tool manufacturing to the highest standards – How Csaba Tool Kft. is setting the course for the future with GROB

In a highly competitive market where precision and delivery reliability are crucial, Csaba Tool Kft. relies on state-of-the-art technologies to meet the requirements of its customers, around 95% of whom come from the automotive industry. "Our greatest strength is our precise and accurate way of working," says Stallmeiszter. "We deliver on time, which is crucial in our industry. But that only works with machines we can rely on 100%."

Technology as a factor for success

When the company was faced with the decision to expand its production capacity in 2022, it quickly became clear that it needed a solution that not only worked at the highest technological level, but also offered a reliable service environment. "For machines used in tool and mold making, it is essential that they adhere precisely to the required tolerances—and that we receive support very quickly in the event of a problem," says Stallmeiszter.

The choice fell on GROB – partly because of the well-thought-out machine concept, which focuses on quality and compactness. After intensive discussions, Csaba Tool Kft. opted for the G550 5-axis universal machining center. In addition to the basic configuration, the machine was equipped with a special high-precision package. This package really shows its strengths in the production of complex mold inserts. It took around seven months from the initial quote to the installation of the machine in the hall – a timeframe that was exactly in line with the Hungarian company’s plans.

Technical advantages that convince

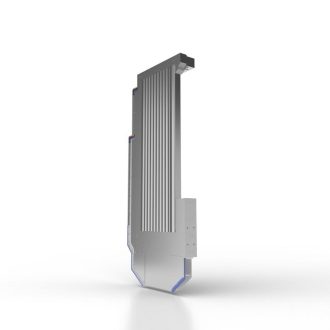

Since then, the investment has paid off for the company. László Gőgh, Production Manager at Csaba Tool Kft., highlights the technical details that make the difference: "The machining area is 800 x 1000 mm, with a spindle movement of almost 1000 mm in the Z-axis. This allows us to optimally machine inserts of approx. 450 to 500 mm – exactly the size we need." He is particularly impressed by the spindle design: "One advantage of this machine is that the length between the spindle nose and the first guide carriage is always the same. This ensures consistently good milling characteristics and optimum stability during machining – which is a huge advantage given our accuracy requirements."

The G550 scores with its innovative machine concept featuring a horizontal spindle position and three linear and two rotary axes. This enables simultaneous 5-axis machining with maximum rigidity and thermal stability. Despite its large machining area, the compact design of the machine ensures a small footprint – an advantage that should not be underestimated in efficiency-oriented production. The side tool changer and optimal chip removal also make the machining center ideal for machining demanding materials, such as those typically found in die and mold industries.

Long-term prospects with GROB

But it’s not just the machine itself that has impressed. The cooperation with GROB has also been consistently cooperative and solution-oriented. "What we appreciate at GROB is their customer-oriented attitude," says Stallmeiszter. "Questions are answered quickly and special requirements are taken into account. This reliability is worth its weight in gold in our business."

For Csaba Tool Kft., the decision to go with GROB was an important step, and one that has already paid off after just a short time. The machine runs reliably, the results are impressive, and the company plans to continue relying on GROB’s technology and experience in the future.

"I am very confident," emphasizes Stallmeiszter in conclusion. "Everything we have experienced with GROB so far reinforces our belief that we made the right decision. The collaboration works— ly on an equal footing and with the same understanding of quality. For us, this is the basis for a long-term partnership."

GROB-WERKE GmbH & Co. KG

Industriestr. 4

87719 Mindelheim

Telefon: +49 (8261) 996-0

Telefax: +49 (8261) 996-268

http://www.grob.de

Marketing, Junior Technical Marketing Managerin

Telefon: +49 (8261) 996-2089

E-Mail: emely.merkle@grob.de

![]()