Invisible but crucial: the importance of cap circumference marking

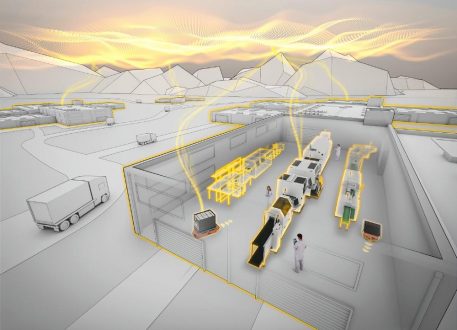

Trotec uses fibre lasers with variable pulse duration to permanently apply serial numbers, minimum thicknesses and standard references. The marking depth is typically 0.1–0.3 mm, and the marking remains legible even after thermal stress. Integration into automated lines takes place via Profinet/OPC-UA interfaces.

In accordance with ECE R90, brake discs must be permanently marked. As requirements for traceability and automated quality assurance increase, cap circumference marking is becoming a data source for MES and ERP systems. Unique identification is particularly crucial in the aftermarket for warranty processing and product liability.

A Tier 1 supplier in Eastern Europe uses Trotec systems to mark over 2 million brake discs annually. The data is transferred directly into the SAP system, enabling seamless traceability.

Trotec Laser, headquartered in Marchtrenk, Austria, is a global leader in the field of laser technology. As part of the TroGroup, the European innovation leader develops, produces and markets high-end laser systems for precise marking, cutting and engraving of various materials and is constantly setting new standards.

Based on over 25 years of experience, Trotec stands for innovative complete laser solutions: Laser machines, extraction systems, powerful software and high-quality materials. 14 sales subsidiaries and a total of around 600 employees support over 40,000 installed systems in 90 countries. The export share is 98 percent, and the current turnover for 2024 is 129 million euros. www.troteclaser.com

Trotec Laser GmbH

Freilinger Straße 99

A4614 Marchtrenk

Telefon: +43 7242 239-7777

Telefax: +43 7242 239-7380

http://www.troteclaser.com

Marketing Solutions

E-Mail: natalie.eichner@troteclaser.com

![]()