parts2clean 2025: Clean bipolar plates for optimum efficiency

Hydrogen technologies play a key role, whether as a central pillar for emission-free mobility or the energy transition. As the heart of a fuel cell or electrolyzer, bipolar plates connected in stacks are central elements. The plates consist of an anode and a cathode with a proton-conducting foil in between. They are made from different materials such as coated metal, graphite, and graphite-polymer compound. Metal bipolar plates are considered to offer benefits in terms of light weight and low volume, as well as possessing good cold-start capabilities. This variant also offers the potential for comparatively cost-efficient series production, which can be further improved through economies of scale.

Bipolar plates take care of gas, heat, and electricity management

In stacks, bipolar plates physically and electrically connect the anode of one cell to the cathode of the neighboring cell. Using integrated flow profiles (flow fields), the plates not only regulate the supply of the reaction gases (hydrogen on the anode side and oxygen on the cathode side), but are also responsible for controlling the temperature of the stacks and releasing water vapor, as well as the thermal and electrical energy. How efficiently they fulfill these multifunctional tasks determines the overall performance of a hydrogen system.

Cleanliness – crucial for quality and efficiency

The production of bipolar plates can be briefly summarized as follows: Unwinding of the extremely thin and very sensitive raw material from a coil, forming it into anode and cathode plates, cutting and separating, as well as coating and joining the plates. The starting material might already be contaminated by rolling and drawing greases, for example, as well as unknown foreign substances from its production; quite apart from and in addition to this, particulate and filmic contamination such as burrs, chips, fibers, dust, oils, emulsions, smoke, and oxides are produced during each of the production steps. Any of these residues can later impair the quality of the bipolar plates, reduce their efficiency and service life, or cause a defect. The requirements for cleanliness are therefore very high. To ensure this high level of component cleanliness, a cleaning process is essential before the joining and coating production steps. A major challenge here is the usually invisible, chemical-film residues on the surfaces, the composition of which is often unknown. In addition, bipolar plates are manufactured at high speed, which means that the required cleaning time is also an aspect to take into account.

Adapted processes and cleaning solutions

Various methods are available for cleaning. These include wet chemical cleaning with solvents and water-based media, laser, steam, and CO2 snow jet cleaning as well as plasma cleaning and hydro-cleaning. These methods are used individually or in combination, depending on the material, the contamination to be cleaned, and the cleaning requirements.

Wet-chemical cleaning has become established in many processes. Oils, greases, and particles can be easily removed with solvents. With water-based media, the downstream drying required in many cases leads to high energy consumption and long cycle times.

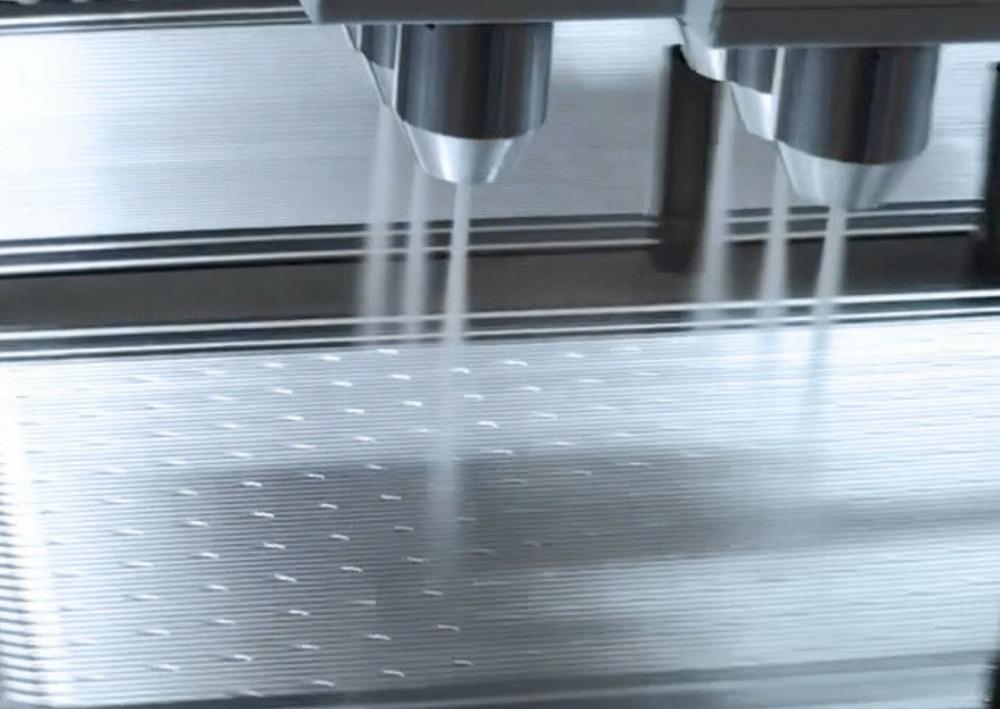

Good results are achieved in very short times when cleaning filmic-chemical and particulate contamination, smoke, and oxides with steam blasting. This is based on the interaction of steam with a proportion of liquid precisely matched to the cleaning task, a high-velocity air flow, and an adapted nozzle concept. Hydro-cleaning has also proven to be effective. The cleaning medium is applied to the surface using nozzles at defined pressures and temperatures.

Dry CO2 snow jet cleaning with liquid carbon dioxide not only enables sludge and oxides to be removed selectively from the complete surface, but also means chemical-filmic contaminants and particles can be cleaned away within very short cycle times. High-pressure (HP) CO2blasting, in which liquid carbon dioxide at a pressure of up to 4000 bar is used as the blasting medium, also represents a promising solution.

In addition to various cleaning systems as chamber and immersion systems, Ecoclean offers the new EcoCvolta, a continuously operating system for cleaning bipolar plates. Tailored to specific requirements, this solution integrates various process options such as spraying, steam cleaning, hydro-cleaning, plasma cleaning, CO2 snow blasting, and drying. The special design of the transport system ensures that the sensitive bipolar plates are handled gently.

Using thermal and photochemical effects, the laser also quickly and reliably removes contaminants such as oxides, smoke, and particles as well as organic impurities. SLCR Lasertechnik has developed an innovative solution for fully automated surface structuring prior to coating and subsequent laser cleaning of bipolar plates. The adhesion properties can be significantly improved by roughening the surface with a laser in the first step. The micro- and nanostructures created increase the specific surface area, which leads to better mechanical anchoring of the coating. The structuring can be adjusted depending on the material and application in order to achieve the best possible wetting with the coating. In the automated solution, processing on both sides is a particular challenge that is overcome by using a specially developed robot gripper. Laser cleaning takes place directly as a downstream second step, which reduces throughput times.

Specific information on procedures

Exhibitors at parts2clean will be providing information about these processes and systems as well as their advantages and limitations. The leading international trade fair for industrial parts and surface cleaning will take place from October 7 to 9, 2025, in parallel with the hy-fcell event (October 7 and 8) at the Stuttgart Exhibition Center (Germany). Visiting both trade fairs and the p2c.EXPERTFORUM is possible with one ticket.

Further information about parts2clean, the exhibition portfolio and the supporting program as well as the presentations of the bilingual p2c.EXPERTFORUM can be found at www.parts2clean.de.

Deutsche Messe AG – parts2clean

Messegelände

30521 Hannover

Telefon: +49 (511) 89-0

Telefax: +49 (511) 89-32626

http://www.messe.de

Presse

Telefon: +49 (711) 854085

Fax: +49 (711) 815895

E-Mail: doris.schulz@pressetextschulz.de

![]()