WISCO awards SMS group the FAC for the successful modernization of its high-capacity hot strip mill in Wuhan

- Final Acceptance Certificate (FAC) issued for the successful modernization of WISCO’s high-capacity hot strip mill in Wuhan

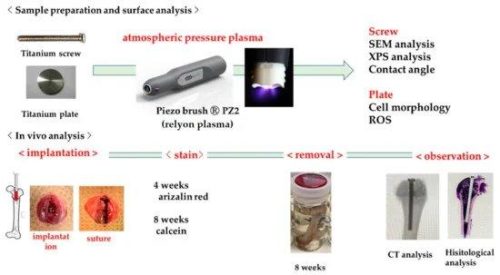

- The project focused on automation upgrades, including X-Pact® Profile, Contour and Flatness Control (PCFC) and new CVC® blocks

- The new upgrades build on earlier improvements (2013–2024), thus strengthening WISCO’s global competitiveness

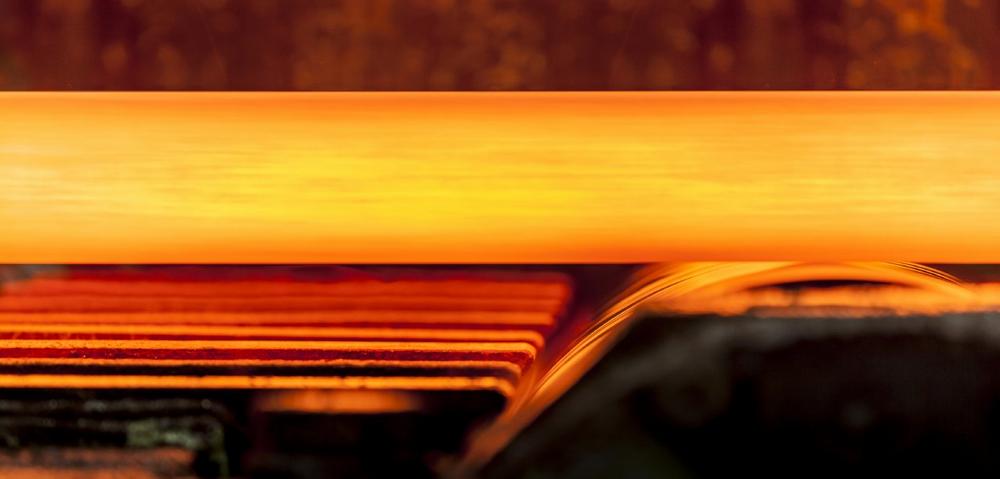

Wuhan Iron & Steel Co., Ltd. (WISCO), a leading Chinese steel producer and part of the China Baowu Steel Group since 2016, has signed the Final Acceptance Certificate (FAC) with SMS group for the successful modernization of its high-capacity hot strip mill (HSM No. 2) in Wuhan, China. The work was carried out under a lifecycle partnership in which SMS group upgrades the mill in multiple stages to keep the plant state-of-the-art, continuously improving production efficiency and product quality.

The hot strip mill, originally delivered by SMS group in 2003, is a 2,250 millimeter mill with an annual capacity of 4.8 million tons. The mill is equipped with state-of-the-art components, including reheating furnaces, a slab sizing press capable of handling slabs 230–250 millimeters thick and 800–2,150 millimeters wide, a two-high roughing mill, a four-high roughing mill, and a seven-stand finishing mill. Final product dimensions range from 1.2–25.4 millimeters in thickness and 700–2,130 millimeters in width, making it a versatile mill capable of producing a wide variety of steel grades.

In this modernization project, SMS group focused on implementing automation upgrades to optimize mill performance and meet WISCO’s objectives. Key elements of the scope included replacement and upgrade of the existing X-Pact® Profile, Contour and Flatness Control (PCFC) system. PCFC is a physical process model that calculates optimal set-points for finishing-mill actuators, such as the Continuously Variable Crown (CVC®) plus work roll bending and shifting systems. In addition to stabilizing the rolling process, PCFC significantly improves product quality, particularly in terms of strip geometry. The PCFC replacement was executed in shadow mode and completed within four weeks, meeting the guaranteed performance targets.

Additionally, the modernization encompassed the installation of new CVC® blocks in rolling stands F1–F7. The CVC® technology enables the axial shifting of rolls with a special contour, allowing continuous adjustment of the roll crown and roll gap profile. When combined with the intelligent PCFC process model, this technique enables precise control of roll bending and shifting to achieve higher profile quality. The upgrades deliver improved strip quality, greater operational stability, enhanced production efficiency and tighter product tolerances for WISCO.

These new enhancements build on a series of prior modernizations that SMS group made to HSM No. 2 between 2013 and 2024. Highlights include a 2013 revamp of downcoiler No. 3 to improve operational reliability; 2018 upgrades adding CVC® bending and shifting on finishing stands F4 and F7 and new slipper-type spindles for roughing mill R2; a new finishing-mill descaler installed in 2019 to improve surface quality; and in 2024, new work roll bending and shifting systems for stands F1–F3 and F5–F6 together with a new X-Pact® PCFC for the entire finishing mill to refine strip shape and thickness control.

The signing of the FAC confirms that all predefined targets have been met and the project is complete. This achievement underscores SMS group’s commitment to delivering advanced technologies and tailored solutions that meet the evolving needs of the steel industry. The modernization of HSM No. 2 not only enhances the mill’s capabilities but also reinforces WISCO’s position as a leading player in the global steel market.

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of around 4 billion euros. SMS is the right partner for challenging projects and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for more than 13,500 employees.

SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Telefon: +49 2161 350-4449

http://www.sms-group.com

Fachpresse

Telefon: +49 2161 350-4449

E-Mail: thilo.sagermann@sms-group.com

![]()