From Standards to Trust: The New Role of Functional Safety in Motion

Hall 3, Stand 3C21

Introduction: Why Functional Safety Exists

Functional safety is the ability of a system to respond safely and predictably when faults occur. The concept was introduced in the late 20th century with standards such as IEC 61508 and ISO 13849. These frameworks were developed for industries like process plants, rail systems, and factory automation where failure could cause catastrophic harm. Despite being available for decades, adoption was slow. Implementing safety standards required significant investment, specialized knowledge, and often clashed with existing machine designs. That reality is changing quickly as robotics and industrial automation increasingly work side by side with people.

By embedding functional safety into the core of their systems, companies can ensure reliability, win customer trust, and scale deployments with confidence. At STXI Motion, this philosophy comes to life in the recently launched optional Safe Motion Module, now available in the flagship ZED65 servo drives and the TIM Integrated Servo Motors.

The Business Value of Functional Safety in Mobile Robotics

Trust and Market Access

Safety compliance accelerates entry into new markets by meeting the strict requirements of international standards. A certified, safety-ready drive can reduce months of risk assessment and shorten the path from prototype to deployment.

Customer Confidence and Adoption

For logistics operators and industrial end users, functional safety is a prerequisite for adoption. Warehouses or factories will not deploy fleets of autonomous robots and other machines, unless they can guarantee that these machines will stop safely, limit speed, or disable torque instantly when required. Features like Safe Torque Off (STO) and Safe Limited Speed (SLS) embedded at the drive level make human–machine collaboration viable.

Cost Reduction Through Smarter Design

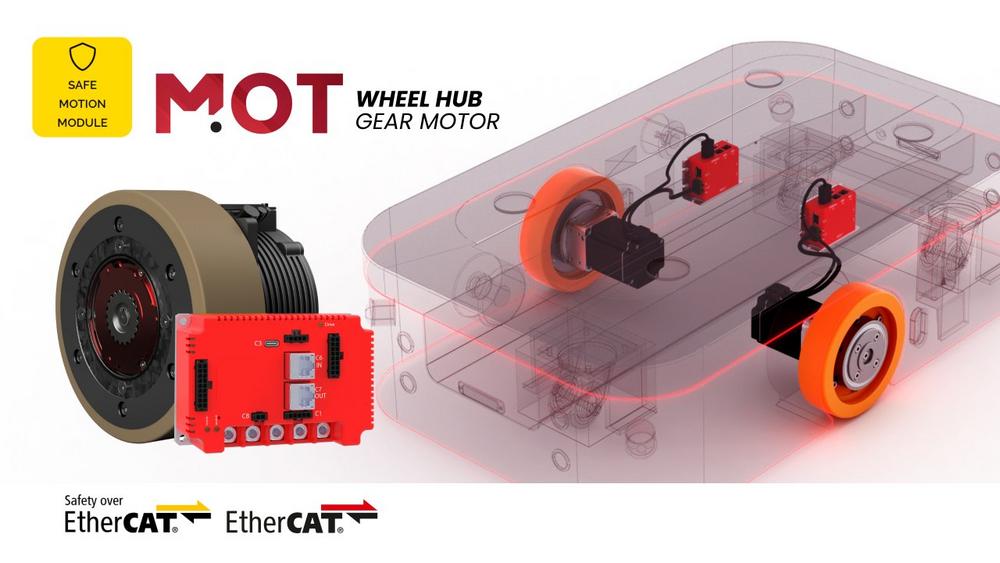

Traditional safety architectures required bulky external cabinets, relays, and complex wiring. By integrating safety directly into compact drives, integrated motors and gearmotors, STXI Motion reduces wiring complexity, saves cabinet space, and lowers maintenance costs. The result is safer, more economical systems that also simplify service. Additionally, the MOT-HM Wheel Hub Gearmotor offers an easily accessible brake, enabling quick maintenance.

Scaling Autonomy

Functional safety is a foundation for scale. Pilot fleets of tens of robots can be closely supervised, but scaling to hundreds across multiple sites demands standardized, embedded safety frameworks. Functional safety also supports scaling in machines: as production systems increase throughput, add more axes, or connect multiple machines into larger lines, safety systems must expand with them. Consistent safety architectures at the drive level maintain predictable responses, protect operators, and ensure efficiency even as systems become larger, faster, or more complex.

Bridging the Gap: From Industry to Field Robotics

Different Safety Environments

In traditional factory automation, risks are controlled by fixed fences, gates, and clearly defined safety zones. In contrast, modern safe machines allow closer interaction with operators, maintenance staff, and other equipment. For example, robot arms can “tend” machines by loading materials, unloading finished parts, and monitoring processes such as CNC machining or injection molding. Functional safety ensures these interactions remain efficient and secure, even at close range.

New Challenges in the Field

Stationary machines as well as robots, moving through warehouses, farms, or construction sites must create “safety zones” using sensors, incl. light curtains, safety mats, lidar, radar, and vision-based systems. Safety here is about adapting to the unexpected: a dropped item or pallet, an interfering worker, and other unforeseen events.

Adapting Standards

Industrial standards like ISO 13849 or IEC 61508 remain relevant, but they must be adapted to new contexts. Industrial machines and mobile robots are guided by standards such as Machinery Directive 2006/42/EC (for machinery and certain components) and ISO 3691-4 (for driverless industrial trucks). The challenge is translating proven industrial practices into new terrains, a task made easier with modular safety-enabled motion platforms.

Technology Enablers

Protocols like FSoE, CIP Safety, and ProfiSafe ensure safe communication. Sensor fusion improves redundancy. Integrated safety in TIM, ZED65 and MOT-HM removes external safety layers, bridging the gap between industrial reliability and mobile adaptability.

The Human Factor

In the field, operators are typically not automation or safety engineers. Designing safety that is intuitive, transparent, and robust ensures correct operation even under pressure. Functional safety is therefore as much about human factors as about hardware and software.

Looking Ahead: Practical Safety Priorities for Builders and Users

As robotics and machines evolve, the future of functional safety is less about futuristic technologies and more about practical improvements that make systems safer and easier to use. Functional safety is becoming more about integrated solutions that are easier to design, configure, and maintain. For machine builders and end users, the priorities ahead are highly practical:

- Drive-level safety integration: Embedding functions like Safe Brake Control and Safe Limited Speed directly in drives and integrated motors reduces wiring and simplifies system design.

- Compact integrated solutions: Combining drive, motor, and safety in one package saves space and installation effort, while improving reliability.

- Service-friendly safety design: Safety also depends on proper maintenance. Accessible brakes and modular subassemblies not only reduce downtime but also ensure that safety features remain operational throughout the life of the system.

- Interoperability across standards: Supporting multiple safety protocols and aligning with international regulations enables global deployment and smooth integration in mixed environments.

- Human-centric design: Safety features must be intuitive, giving operators and maintenance staff clear feedback and minimizing the chance of error.

- Predictive diagnostics: Safety-enabled drives and motors increasingly include monitoring of conditions such as brake wear or overheating, alerting users before failures occur, and preventing unsafe situations.

Conclusion: Safety as a Market Differentiator

Functional safety has moved far beyond being a regulatory requirement. In mobile robotics and industrial automation, it now defines competitiveness. It reduces costs, accelerates certification and maintenance, enables safe scaling, and builds trust between humans and machines.

With solutions like the TIM integrated motor, ZED65 servo drive and the MOT-HM Wheel Hub Gearmotor with optional functional safety, STXI Motion is setting a new benchmark, offering state of the art solutions in the industry with a wide range of safety functions. This makes functional safety not just a protective layer, but a core enabler of the future of industrial machines and robotics.

STXI Motion GmbH

Erich-Sanders-Weg 5

41749 Viersen

Telefon: +49 (2162) 14469-06

http://www.stxim.com

Strategic Marketing Manager

Telefon: +972 (74) 7776899-115

E-Mail: roni.kedar@stxim.com

![]()