Pushing the limits of precision and reliability

EAGLEYARD’s CEO Claus Heitmann emphasizes: “We are proud to contribute our expertise and innovative products to this extraordinary mission with NASA demonstrating the power of collaboration and trust across borders. As a Berlin-based high-tech company, it is a special honor to be part of this visionary partnership and to drive excellence in the most demanding space applications.”

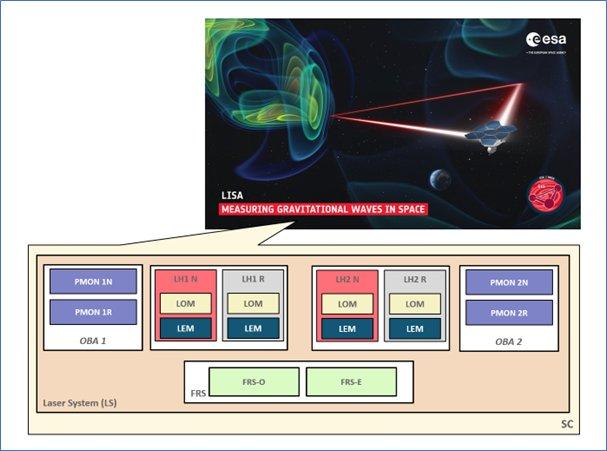

The Laser Interferometer Space Antenna (LISA) will be the first space-based observatory dedicated to studying gravitational waves. Led by ESA, LISA is made possible by a collaboration between ESA, its member states, NASA, and an international consortium of scientists. Scheduled for launch in 2035, LISA will consist of three spacecrafts flying in a giant equilateral triangle, each 2.5 million kilometers apart, trailing or leading Earth in orbit around the Sun. LISA operates as a heterodyne laser interferometer, detecting infinitesimal changes in distance – on the order of picometers – caused by passing gravitational waves. Each spacecraft carries two test masses and a drag-free control system to ensure near-perfect free-fall conditions. NASA’s contribution of the Laser System aboard each satellite includes four laser heads (LH), a Frequency Reference System (FRS) based on an ultra-stable optical cavity (figure 1), and four power monitor (PMON) detector assemblies that reside on two optical bench assemblies (OBA) built by the UK Astronomy Technology Centre. In total, the constellation hosts 12 laser heads, with six active at any time. One laser is frequency-locked to the FRS, while the remaining lasers are offset phase-locked and function as transponders, implementing bi-directional optical links to maintain precise interferometry over millions of kilometers.

LISA will be able to detect gravitational waves from events involving supermassive black holes, measuring relative displacements smaller than the diameter of an atomic nucleus—a performance level that pushes the boundaries of modern engineering.

For the groundbreaking LISA mission, TOPTICA EAGLEYARD provides a key enabler of the system’s optical performance: the RWL 808 nm laser diode, delivered as a custom Chip-on-Carrier (CoC). This high-efficiency pump laser plays a crucial role in the µNPRO (micro Non-Planar Ring Oscillator) – the main oscillator at the heart of each spacecraft’s laser system. Designed by NASA GSFC around a neodymium-doped YAG crystal with a space compatible miniaturized ring-resonator architecture, the µNPRO converts the 808 nm pump light into a highly stable 1064 nm single-frequency output (see figure 2).

Dr. Anthony Yu, NASA Goddard’s lead for the LISA Laser System explains “As a U.S. federal agency, NASA is always looking within the nation’s borders before turning to international suppliers. The search for a suitable laser diode for the µNPRO was no exception. That’s where EAGLEYARD came into play. For the LISA program, we couldn’t have asked for a better partner. Having already built a relationship of trust through previous projects, we knew they could deliver on their promises – and they did. It’s a rare and powerful moment when such a unique product as the RWL 808 nm doesn’t just get built, but even tested by a company you trust 100%. A perfect match – and a collaboration we’re proud to deepen.”

The RWL 808 nm stands out not only for its compact format and beam quality but also for its ability to deliver reliable, long-term performance under space conditions. Its integration into the µNPRO highlights its critical function: enabling precision interferometry across millions of kilometers.

To meet the mission’s thermal and reliability demands, the carrier is providing superior heat conductivity. LISA operates the lasers in derated mode at 400 mW – half their commercial capacity – to leave headroom for so-called hot-sparing redundancy requirements meeting the mission lifetime goal of >10 years. Despite the derating, the RWL 808 nm still delivers impressively stable singlemode power with excellent beam properties.

Following a strict quality policy for space applications, where reliability must be verified for each individual wafer in use, the laser diode has to undergo full qualification, including 10,000-hour aging tests on custom-built equipment, as long-term performance under the harsh conditions of space requires more than standard procedures.

To meet such demanding requirements, e.g. achieving high test temperatures of more than 70°C under well controlled heat dissipation management, EAGLEYARD developed a fully customized in-house aging test platform. Commercially available standard test systems proved insufficient for the high thermal load and power levels of the RWL 808 nm laser diodes, running continuously for a year or even longer. Recognizing the need for a more robust, accurate and durable solution, EAGLEYARD launched a multi-million strategic investment initiative in 2020 to design proprietary lifetime test equipment which is in full service now.

The result is the "LISA Laser Aging Test Tower"—a highly specialized test system capable of running 10,000-hour aging tests on up to 40 individual laser devices, each with precise, software-controlled monitoring of six critical parameters, including optical power and heat sink temperature. Complementing the system is a custom-developed test rail, optimized for accuracy through 4-wire connections and high-end materials (figure 3). This system was designed and built by EAGLEYARD, and successfully validated together with NASA, underlining EAGLEYARD’s deep competence not only in photonics, but also in advanced test engineering.

The project has now entered Phase 2, with the upcoming production of Flight Modules. Lasers are selected from multiple wafers, optimized individually, and representative units subjected once again to extensive 10,000-hour aging tests in the LISA Laser Aging Test Tower. At the end, more than 100 of Flight Model CoCs that are suitable for the mission will be delivered for further laser system integration and testing.

“Working jointly together for many years in that program, we are glad to state that we have passed an ordinary supplier-customer relationship by far, it has been outpassed by two extraordinary engineering teams collaborating complementary and thriving laser diode performance and reliability beyond its limits.” summarizes Michael Kneier, VP Sales & Marketing at EAGLEYARD. With this approach, EAGLEYARD demonstrates its role not only as a high-end laser diode supplier, but as a long-term engineering partner committed to meeting the highest standards of space-grade quality and reliability.

About TOPTICA EAGLEYARD:

TOPTICA EAGLEYARD is based in Berlin, Germany, and is a leading supplier of high-power laser diodes with wavelengths ranging from 630 nm to 1120 nm. TOPTICA EAGLEYARD’s products are used around the globe and combine maximum performance and unparalleled service life with excellent beam quality, making them especially suitable for industrial, medical, scientific, and space applications. TOPTICA EAGLEYARD was founded in 2002 as a spin-off from the renowned Ferdinand-Braun-Institute (FBH). Today, it plays a leading role in its sector thanks to its exceptional GaAs-based laser diode portfolio. By properly and professionally applying its expertise, experience and know-how, it has developed research results into marketable products that are sold worldwide, either directly or through partners. TOPTICA EAGLEYARD has been part of the TOPTICA Group since 2013. Find out more at www.toptica-eagleyard.com.

eagleyard Photonics GmbH

Rudower Chaussee 29

12489 Berlin

Telefon: +49 (30) 63924520

Telefax: +49 (30) 63924529

http://www.toptica-eagleyard.com

Senior Marketing Manager

Telefon: +49 (30) 63924561

E-Mail: stephanie.hannibal@toptica-eagleyard.com

![]()