BT-Systems: Preferred System Partner for Highly Automated In-tralogistics – From Europe to North America

Hall 1, Booth 1H17

Comprehensive Intralogistics Solutions for Global Challenges

Rising production volumes, limited floor space, and the need for maximum energy and process efficiency are creating increasingly complex logistical demands for industrial companies worldwide. BT-Systems meets these challenges with fully automated intralogistics solutions, positioning itself as a preferred system partner for advanced warehouse and material flow technologies.

Flagship Project in North America: Fully Automated High-Bay Warehouse for Sofidel

A current milestone is the construction of a fully automated high-bay warehouse for Sofidel in Duluth, Minnesota, USA. As part of a USD 200 million investment program, BT-Systems is delivering a state-of-the-art facility offering approximately 35,000 pallet positions. Five stacker cranes, double-mover shuttles, and an intelligently networked conveyor system ensure high throughput, optimal space utilization, and reduced energy consumption.

Innovative Technology and Competence Centers for Maximum Efficiency

The complete technical solution is engineered by ECE-LOG, BT-Systems’ competence center for warehouse and intralogistics, together with AAT, the competence center for industrial conveyor systems. Warehouse management software, PLC controls, and fully integrated material flow systems guarantee stable, transparent, and future-proof operations.

360° Responsibility from a Single Source

As general contractor, BT-Systems assumes full responsibility for system planning — covering mechanics, conveyor technology, software, control systems, safety, and fire protection. This expertise is strengthened by the REDWAVE competence center in the USA, ensuring fast on-site implementation as well as long-term service and maintenance support.

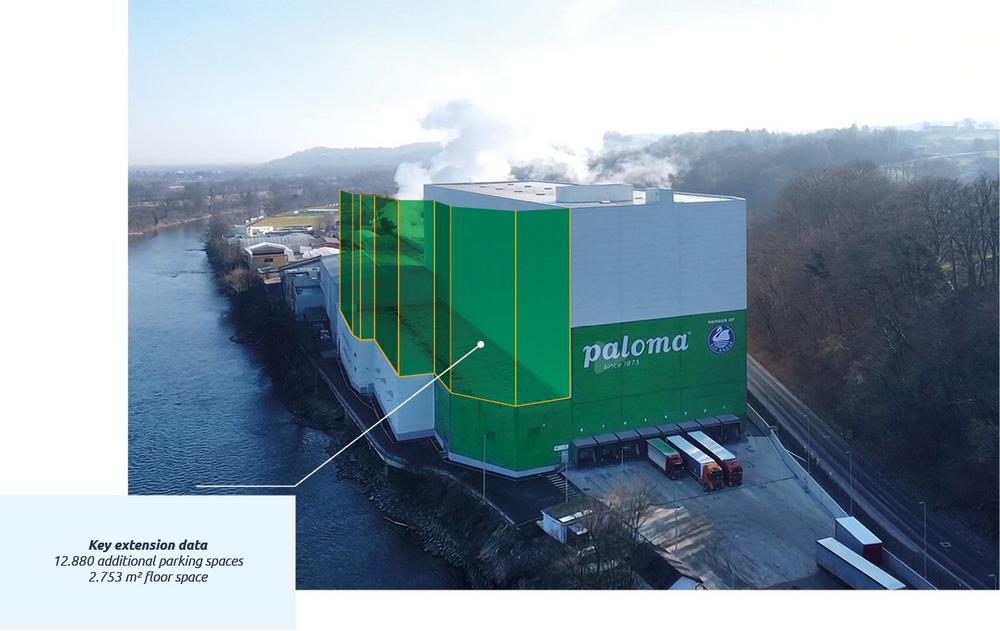

Long-Term Partnerships: Expansion of the Paloma High-Bay Warehouse

BT-Systems’ ability to build sustainable customer relationships is exemplified by its long-standing collaboration with Paloma, a leading hygiene paper manufacturer in Southeastern Europe. Following the successful commissioning of a fully automated high-bay warehouse in 2024, BT-Systems has once again been entrusted with expanding the facility. The objective: accommodate rising production volumes within minimal space — achieved through a highly compact warehouse design, a Mover-Trolley system, and seamless integration with both existing and new production lines.

Customer-Oriented End-to-End Systems

“Today, our clients are not looking for isolated solutions; they want reliable end-to-end systems that evolve with their needs,” says Thomas Lafer, Head of Competence Center ECE-LOG at BT-Systems GmbH.

LogiMAT 2026: Experience Automation, Space Efficiency, and Sustainability First-Hand

At LogiMAT 2026, BT-Systems will demonstrate how automation, space optimization, sustainability, and investment security combine to create future-proof intralogistics solutions — scalable, international, and delivered from a single source. The team looks forward to welcoming visitors in Hall 1, Booth 1H17.

Further Information:

www.bt-systems.at

www.ece-log.at

www.aat.at

BT-Systems GmbH

Ludersdorf 175

A8200 Ludersdorf-Wilfersdorf

Telefon: +43 (3112) 5580-0

Telefax: +43 (3112) 5580-4

https://bt-systems.at

International Marketing

Telefon: +43 (664) 80051-2276

E-Mail: a.thaller@bt-systems.at

![]()