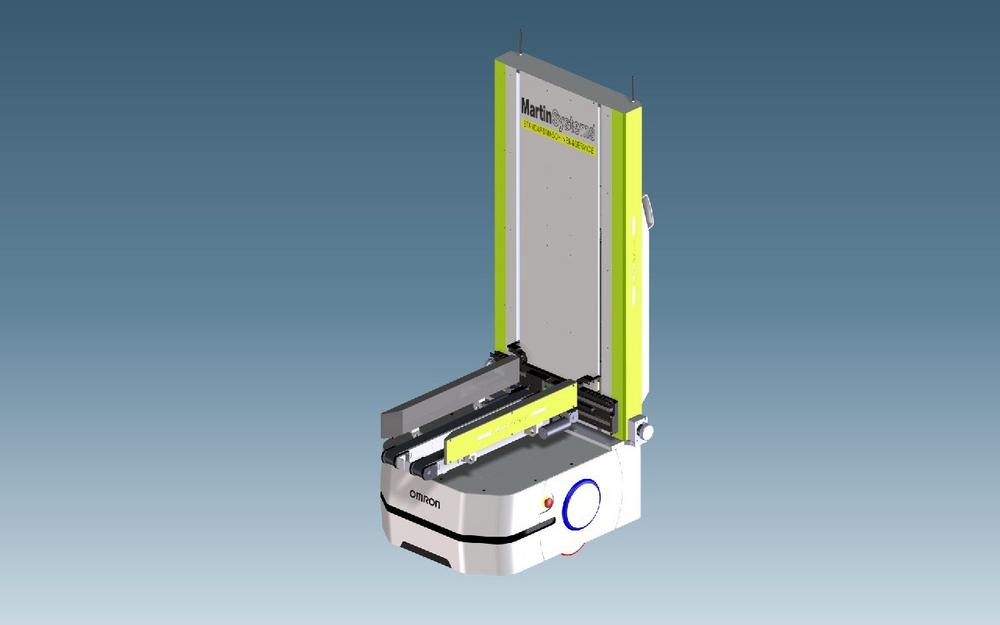

MartinSystems presents an AMR solution at LogiMAT 2026 in Stuttgart that flexibly adapts to your production.

At LogiMAT 2026, MartinSystems sets new standards: The MBT 08 opens up maximum flexibility in intralogistics – without modifications and compromises. The innovative, width-adjustable lift safely transports a wide range of container sizes with just a single AMR. This eliminates costly standardization and the use of multiple specialized robots.

Thanks to compact dimensions, the MBT 08 remains highly maneuverable and space-saving even at full functionality. Existing passive handover stations can continue to be used – your production keeps running while automation comes in.

Thoughtful ergonomics, a standard HMI within optimal reach, easily accessible emergency stop switches, and side-integrated safety scanners ensure quick commissioning and safe, comfortable operation in industrial daily use.

The sturdy lift construction with a braking stepper motor guarantees the highest production safety – even in an emergency stop. The system is rounded off by a modern, high-quality design that immediately shows: here runs a future-proof solution for your production.

MBT 08 – reduces complexity, saves costs, and gains maximum flexibility. Visit our booth (8F20) at LogiMAT in Stuttgart to see the autonomous mobile robot live in action and to learn more about MartinSystems’ advanced technologies.

As a company, MartinSystems stands for the highest quality and innovation. Our motto "We build machines for your success through a productive future" reflects our claim to develop tailored solutions that help our customers succeed.

For more information, feel free to arrange an appointment with our team on site or visit our website at www.MartinSystems.eu.

Standard automation at the highest level: this is the stated corporate goal of MartinSystems. For different industries and their suppliers, the sister company of the over 50-year-old special machine builder MartinMechanic offers a unique modular system for automation of production processes and intralogistics. MartinSystems’ product portfolio consists of standardized automation cells, induction hardening machines, tool storage systems for machine tools, and intralogistics solutions based on autonomous mobile robots – all also turnkey. The compact standard systems can, among other things, automatically load and unload, equip, feed parts, store, and eject them. Induction hardening machines are used wherever parts are hardened, welded, annealed, or shrink-fit. And with the help of tool stores, machine tools can be expanded in a space- and cost-saving way. Autonomous mobile robots offer clever intralogistics solutions that can complement or replace traditional distribution concepts. Through standard automations, mature solutions are offered for many applications that can be integrated quickly and cost-effectively into existing production processes

MARTIN Systems GmbH

Friedrichstr. 95

10117 Berlin

Telefon: +49 (30) 20059700

http://www.martin-membrane.de

Marketing

Telefon: +49 (74) 5284667-0

E-Mail: info@MartinSystems.eu

![]()