OptiSense presents new industrial sensors: Coatng thickness sensors with built-in tme saver

The greater the time pressure, the more valuable the savings in working time. This is particularly true in plant engineering in the coating industry. For project managers and integrators, the search for time-saving solutions is therefore essential. An intelligent example to speed up projects are the OptiSense PaintChecker Line and PaintChecker Angle sensors.

For many plant engineers, time saving is an important factor when choosing sensors – especially as the miniaturized high-performance sensors from OptiSense not only pay off during initial installation, but also during operation.

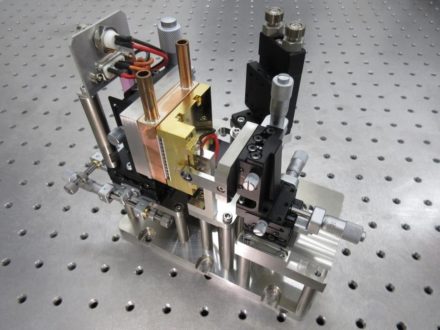

Thanks to their robust industrial housing, the new generation of OptiSense laser sensors PaintChecker Industrial Line and the folded version PaintChecker Angle can be operated even under harshest environmental conditions. And replacing the sensors runs smoothly and quickly as well without the need for complex brackets.

The sensors feature a diode laser as a light source – with all the advantages of semiconductor technology, such as long durability, high efficiency and absolute vibration resistance. The coating thickness measurement range is from 1 to 1,000 μm.

The optimized thermal design enables continuous operation at high measurement rates of up to 2.5 Hz. The laser sensors meet IP 50 rating, weigh 330 g and measure 38 x 36 x 104 mm for the PaintChecker Line and 77 x 36 x 65 mm for the PaintChecker Angle sensor. The Industrial sensors are also available as high-power versions. The models equipped with LARES®–technology are eyesafe.

OptiSense GmbH & Co. KG

Annabergstraße 120

45721 Haltern am See

Telefon: +49 (5254) 933343

http://www.optisense.com

Telefon: +49 (163) 3933343

E-Mail: hostmann@optisense.com

![]()