SMS group and Acciaierie d’Italia successfully bolster production reliability for tandem cold mill

- Service activities targeted significant wear on the rotary mandrel after 15 years in operation, focusing on the spherical plain bearings and replacing essential components

- Proactive service guaranteed long-term production reliability and minimized downtime risks for the mill

- The decision to repair the rotary mandrel on site, coupled with 24-hour operation during the repair work, enhanced the cold rolling mill’s efficiency

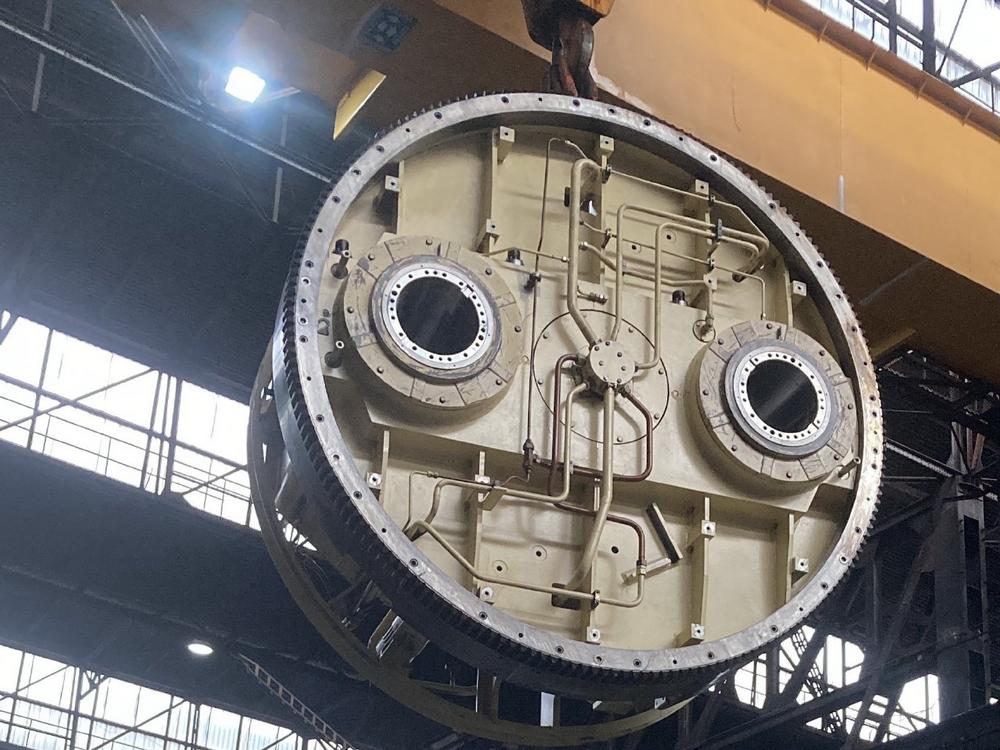

In a remarkable on-site operation, SMS group has successfully modernized the rotary mandrel in the tandem cold rolling mill at Acciaierie d’Italia (ADI) in Genoa, Italy. The cold rolling mill plant in Genova is sole in Italy for its ability to produce approximately 1.5 million tons of tinplate and electrolytic chrome-coated strip annually, which is largely used in the food processing industry. After 15 years of continuous production, the project aimed at addressing significant wear, particularly focusing on the spherical plain bearings, which necessitated comprehensive repairs. To maintain the performance and reliability of the plant, other key components such as hollow shafts, spur gears, bearing shafts, and support rollers were replaced.

This proactive service approach, combined with the strategic decision to perform on-site repairs, resulted in significant savings for ADI, while at the same time minimizing the risk of unplanned downtimes. Both initiatives collectively bolstered the long-term production reliability of the cold rolling mill, sustainably enhancing the plant’s efficiency and stability. The 24-hour operation during the repair work enabled a swift resumption of production.

Since 2019, SMS has regularly conducted site inspections to closely monitor the condition of the rotary mandrel. This allowed SMS experts to identify maintenance needs in advance. In 2022, critical wear on the spherical plain bearings was detected and maintenance measures were immediately initiated. ADI was able to organize all necessary spare parts in advance and make optimal preparations for the repair, thanks to SMS’s timely reporting.

With a diameter of four meters and a weight of 55 tons, the rotor replacement was a significant challenge. Yet, through meticulous planning, the rotor was safely lifted for repairs. State-of-the-art technologies such as induction heating devices and hydraulic tightening systems up to a metric size of M80 were employed to install the spherical plain bearing, which has an outer diameter of 900 millimeters, thus ensuring reliable, high-precision plant functionality.

Acciaierie d’Italia expressed its satisfaction with the collaboration, stating, “The partnership with SMS group has proven invaluable for the maintenance and optimization of our plant. Thanks to precise planning, innovative technologies, and seamless coordination, we efficiently implemented the repair of our rotary mandrel, saving valuable time and costs while improving the plant’s reliability and performance.”

Christian Werner, Solutions Flat Products at SMS, commented, “This project underscores the importance of close collaboration with our customers. Our proactive diagnosis and precise planning not only restored operational safety but significantly reduced downtime and costs for Acciaierie d’Italia. We are proud to support ADI in sustainably optimizing their plants.”

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of around 4 billion euros. SMS is the right partner for challenging projects and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for more than 13,500 employees.

SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Telefon: +49 2161 350-4449

http://www.sms-group.com

Fachpresse

Telefon: +49 (211) 881-4449

Fax: +49 (211) 881-774449

E-Mail: thilo.sagermann@sms-group.com

![]()