Compact and flexible: KHS Innoket AutoReel reduces operator intervention

With the KHS Innoket AutoReel, the Dortmund systems supplier has developed a labeling system for PET bottles that meets the ever-growing requirements of faster and faster, increasingly powerful production lines. “The vast production speeds of modern systems present a number of new challenges,” explains Cornelius Adolf, product manager for labeling technology at KHS. “On such high-performance lines, an operator would have to attend to the labeling station more or less every 15 minutes to insert a new label reel.” With the KHS Innoket AutoReel, however, a line runs for up to eight hours without any operator intervention being necessary.

Operator-friendly design

The focus during development was also on extreme ease of operation: the ergonomic drawer system benefits operators as it gives them optimum access. New reels can thus be individually refilled during ongoing operation without production having to be interrupted. “The drawers can be opened separately to insert a new reel. Only the drawer that’s actually in operation is locked,” Adolf continues. The integrated buffer system ensures that there is a constant web tension between the reel magazine and labeling station and thus makes for a stable production process. While reels are being changed and spliced on the KHS Innoket AutoReel, the labeling station continues unhindered without impacting the line performance.

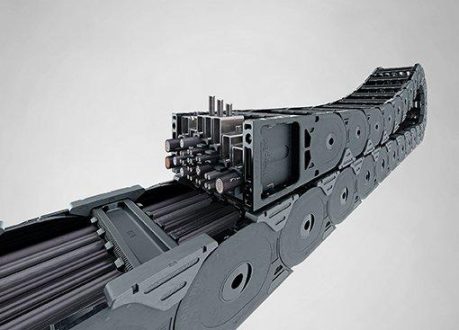

Compact and flexible

The KHS Innoket AutoReel is suitable for all standard types of roll-fed label and can be flexibly integrated into existing lines featuring KHS Innoket Neo RF labeling machines or KHS InnoPET TriBlocks. Thanks to the reel array, the KHS label reel storage system is particularly compact while still providing space for eight reels. The unit’s design and the possibility for flexible installation distance and angle to the labeling station make it perfect for use in production shops where space is limited.

The KHS Group is one of the world’s leading manufacturers of filling and packaging systems for the beverage and liquid food industries. Besides the parent company (KHS GmbH) the group includes various subsidiaries outside Germany, with production sites in Ahmedabad (India), Waukesha (USA), Zinacantepec (Mexico), São Paulo (Brazil) and Kunshan (China). It also operates numerous sales and service centers worldwide. KHS manufactures modern filling and packaging systems for the high-capacity range at its headquarters in Dortmund, Germany, and at its factories in Bad Kreuznach, Kleve, Worms and Hamburg. The KHS Group is a wholly owned subsidiary of the SDAX-listed Salzgitter AG corporation. In 2024 the KHS Group and its 5,626 employees achieved a turnover of around €1.654 billion.

KHS GmbH

Juchostr. 20

44143 Dortmund

Telefon: +49 (231) 569-0

Telefax: +49 (231) 569-1541

http://www.khs.com

external PR consultant

Telefon: +49 251 6255 6123

E-Mail: khs@information-presse.de

![]()