Traceability Directly on the Component

With the SpeedMarker and InMarker series, Trotec offers powerful industrial lasers that can be flexibly adapted to customer-specific requirements – from stand-alone workstations to fully automated inline integration.

Direct Part Marking as a Key to Industry 4.0

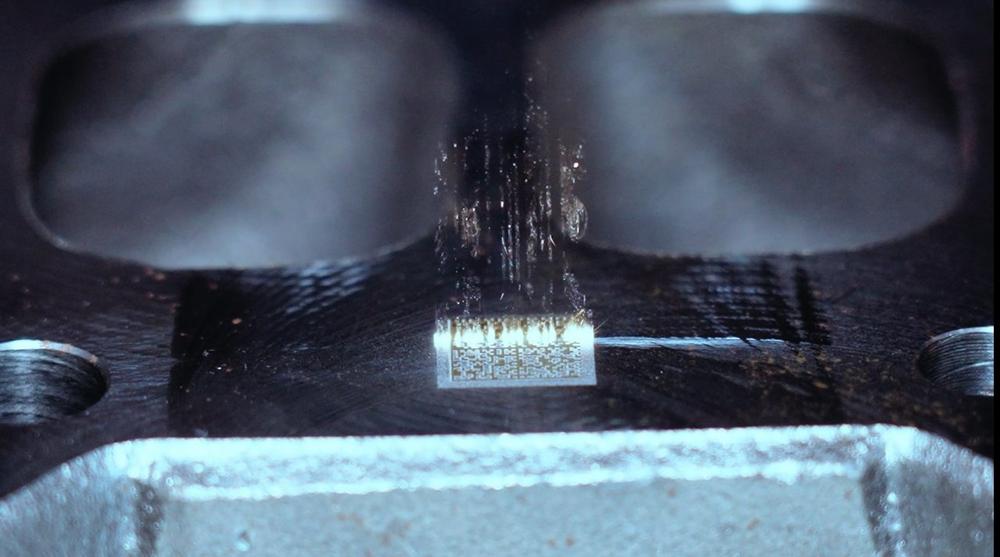

Direct Part Marking (DPM) enables information such as serial numbers, production data, or batch codes to be stored permanently and securely directly on the component. DPM not only increases quality and safety but also reduces production costs and optimizes the supply chain. The marked data is transferred directly into the ERP system, ensuring end-to-end transparency.

According to a recent white paper by Quality Magazine, modern laser marking solutions enable durable and material-specific marking – a decisive advantage given the increasing complexity of components, such as those in the automotive sector. Automotive IQ also emphasizes the central role of DPM in traceability and product safety in the automotive industry.

Cost Efficiency Meets Process Integration

Compared to conventional methods such as labels or dot peen marking, laser marking with Trotec systems is up to ten times more cost-effective. Machines from the SpeedMarker or InMarker series can be seamlessly integrated into existing production processes and lines. Thanks to ERP connectivity, data can be transferred automatically – a clear advantage for companies seeking efficiency and scalability.

Cross-Industry Applications

Whether in mechanical engineering, automotive, rail, electronics, or medical technology – Trotec solutions are highly versatile. The combination of robust laser technology, intuitive software, and flexible system integration makes them the ideal choice for a wide range of production environments.

Standards-Compliant and Future-Proof

The markings comply with international standards such as ISO 28219 and ISO/IEC 29158, which define the readability and quality of DataMatrix codes. This makes Trotec systems ideally suited for global use and ensures the highest standards of traceability and quality assurance.

Conclusion: Traceability That Pays Off

“Our customers value the combination of cost-efficiency, process reliability, and easy integration,” says a Trotec spokesperson. “With the SpeedMarker and InMarker series, Trotec offers solutions that make traceability economical, standards-compliant, and future-ready – for every industry and every production environment.”

More information: https://www.troteclaser.com/…

Trotec Laser, headquartered in Marchtrenk, Austria, is a global leader in laser technology. As part of the TroGroup, the European innovation leader develops, manufactures, and markets high-end laser systems for precise marking, cutting, and engraving of various materials, continuously setting new standards.

Based on over 25 years of experience, Trotec stands for innovative complete laser solutions: laser machines, extraction systems, powerful software, and high-quality materials. Fourteen sales subsidiaries and a total of around 600 employees support the more than 40,000 systems installed in 90 countries to date. Exports account for 98 percent of sales, with current sales in 2024 at 129 million euros. www.troteclaser.com

Trotec Laser GmbH

Freilinger Straße 99

A4614 Marchtrenk

Telefon: +43 7242 239-7777

Telefax: +43 7242 239-7380

http://www.troteclaser.com

Marketing Solutions

E-Mail: natalie.eichner@troteclaser.com

![]()