KHS and SLMG Beverages: Right on time

With more than 240 million residents, Uttar Pradesh in the north of India is the most populated state on the subcontinent. It’s also home to a representative section of this extremely ethnically, linguistically and religiously diverse country, as here especially the cultures of the north meet those of the south. The climate is also extreme: during the hot months of March to July, temperatures can soar to a maximum of 50°C. For the people of this region, sufficient intake of fluids is therefore essential to their survival.

Accordingly, the potential for the beverage industry is huge. Up until 15 years ago, carbonated soft drinks were still the privilege of rich and middle-class families. This has changed: soda pop is now affordable for and accessible to all levels of society, which in view of the logistical challenges prevalent in India is not necessarily a given.

Biggest Coca-Cola bottler in India

One of the country’s big players is Coca-Cola India. The concern itself assumes responsibility in particular for local brand management and marketing. Production and distribution are managed entirely by independent regional bottlers. The largest of these is SLMG Beverages, a consolidation of four bottlers all run by brothers of the Ladhani family of entrepreneurs. They’ve worked for Coca-Cola in Uttar Pradesh and its neighboring regions for more than 30 years. Through the takeover of a further bottler, they recently also secured the license for the state of Bihar. This means that in the future the company will supply around 350 million people with soft drinks. One of its eight associated filling facilities is located in Chhata, not far from the culturally significant metropolis of Agra with the world-famous Taj Mahal.

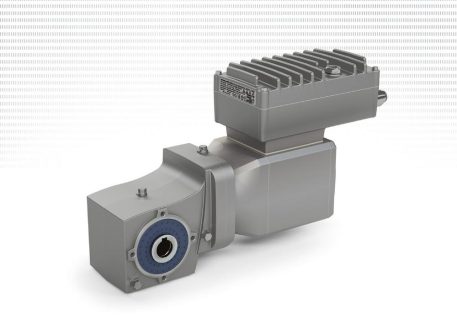

Growth engine TriBlock

The newest of the six beverage lines in Chhata was delivered and installed by KHS. The heart of the line is the InnoPET TriBlock, a modular block system comprising a stretch blow molder, roll-fed labeler and filler that’s particularly low on space. It processes up to 48,000 non-returnable PET bottles an hour holding between 250 milliliters and two liters. During the high season, the main focus is on small single-serve formats.

“In 2023, our output rose by almost 35% over the previous year and in 2024 we again grew by 25%,” explains Sriharsha Chilukuri, who is senior general manager of the plant. “We produce approximately 60% of our soft drinks in PET bottles on the new line.”

High tempo

KHS and SLMG Beverages have been working together for a long time. “We’ve been procuring machines from KHS since we started bottling for Coca-Cola,” says Chilukuri. The most recent examples are two Plasmax machines that coat the insides of PET bottles with an ultra-thin layer of glass. This protects the contents against oxygen pickup and carbon dioxide loss, thus preserving the product’s taste and extending its shelf life. The Dortmund systems supplier was now able to secure the companies’ first joint line project with its InnoPET TriBlock, well known for its low consumption. Various technological aspects, such as efficiency and an in-house roll-fed station for hot-melt, wrap-around label application, formed the key criteria for being awarded the contract. The promise of quick project implementation in time for the start of the high season ultimately clinched the deal; it’s during these few months that the company makes about 80% of its annual turnover. Just 40 days passed from delivery of the machines through installation to validation of the first bottle – an exceptional tempo, as Chilukuri happily remarks.

Outstanding performance

The local team at KHS’ Indian production site in Ahmedabad in particular have every right to be proud of this achievement: besides supplying the conveyors and palletizers manufactured themselves on site, they also handled the installation and commissioning of the line.

The result had all those involved convinced. “During acceptance, the line ran for ten hours without disruption,” remembers Dharmesh Baria, project manager for after sales and service at KHS. “This amounts to a performance of 99.96%.”

Local presence a success factor

Besides the technology, Chilukuri primarily appreciates the good relations enjoyed by the two companies. “Our relationship goes beyond the usual OEM/customer cooperation. As business partners, we’re on an equal footing and see ourselves as a team that works as one.” One important reason for this is KHS’ local presence. “This is a distinguishing criterion. KHS’ experts are available to us at any time and we can rely on getting exactly the kind of support we need.”

It’s clear that SLMG Beverages has big plans: over the last few years, the bottler has invested almost €400 million in cutting-edge plant engineering. To date, the enterprise has grown annually by around 20 to 25%. In 2025 it intends to boost its turnover to over a billion euros – not least thanks to its recent regional expansion. This means that SLMG Beverages will generate the biggest share of Coca-Cola sales in the most populous country in the world – in partnership and with the support of KHS.

The KHS Group is one of the world’s leading manufacturers of filling and packaging systems for the beverage and liquid food industries. Besides the parent company (KHS GmbH) the group includes various subsidiaries outside Germany, with production sites in Ahmedabad (India), Waukesha (USA), Zinacantepec (Mexico), São Paulo (Brazil) and Kunshan (China). It also operates numerous sales and service centers worldwide. KHS manufactures modern filling and packaging systems for the high-capacity range at its headquarters in Dortmund, Germany, and at its factories in Bad Kreuznach, Kleve, Worms and Hamburg. The KHS Group is a wholly owned subsidiary of the SDAX-listed Salzgitter AG corporation. In 2024 the KHS Group and its 5,626 employees achieved a turnover of around €1.654 billion.

KHS GmbH

Juchostr. 20

44143 Dortmund

Telefon: +49 (231) 569-0

Telefax: +49 (231) 569-1541

http://www.khs.com

external PR consultant

Telefon: +49 (251) 6255-6123

E-Mail: khs@information-presse.de

![]()