-

Empowering Industrial Upgrading Worldwide: Lead Intelligent Equipment Leads Energy Storage with Smart Turnkey Manufacturing

With the global momentum behind carbon neutrality ("dual-carbon" goals), the energy storage industry is entering a phase of explosive growth. Behind this surge lies a pressing need for greater production efficiency, optimized costs, and advanced intelligent manufacturing. As a global leader in new energy equipment, Lead Intelligent Equipment ("LEAD") is delivering powerful momentum to energy storage players worldwide through its turnkey, full-process intelligent manufacturing solutions, becoming a core driver of high-quality industrial development. Integrated Solutions Driving Industry Transformation LEAD Intelligent has moved beyond the traditional single-point equipment supply model by creating a comprehensive intelligent manufacturing ecosystem. This full value chain solution spans from cell manufacturing and module/PACK assembly to charge-discharge…

-

LEAD Launches Advanced Solution for Battery Formation and Grading, Setting New Standards in Energy Efficiency and Cost Optimization

Lead Intelligent Equipment (hereinafter referred to as "LEAD"), a global leader in intelligent manufacturing solutions, has introduced a cutting-edge battery formation and grading system designed to significantly reduce energy consumption, lower operational costs, and enhance production consistency for lithium battery manufacturers. As demand for lithium batteries continues to surge worldwide, traditional formation and grading processes have become a bottleneck—plagued by high energy usage, limited precision, and costly maintenance. LEAD’s new system offers a comprehensive answer to these challenges, helping manufacturers increase efficiency and competitiveness through smart, sustainable innovation. Three Key Innovations in Water-Integrated Thermal System Design LEAD’s latest-generation solution delivers three major advancements in formation and grading performance: Precision Temperature…

-

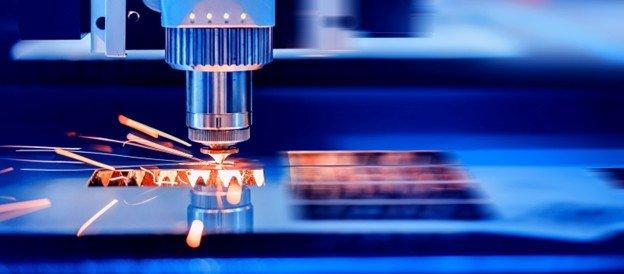

LEAD Launches High-Speed Dry Coating Line

LEAD Intelligent Equipment, a global leader in smart manufacturing for the new energy sector, has officially launched its mass-production integrated dry mixing and coating system for lithium battery anodes and cathodes. Purpose-built for industrial-scale production, the system introduces a solvent-free, energy-efficient solution that sets a new benchmark for clean, high-performance battery manufacturing. As global battery demand skyrockets and environmental regulations tighten, coating remains a core process in intelligent battery production—one that plays a critical role in overall battery performance. While traditional wet coating methods are widely used, the drying stage alone accounts for over 35% of total energy consumption in cell manufacturing. Additionally, solvent use presents ongoing challenges in terms…

-

Lead Intelligent Equipment Showcases Advanced Battery Manufacturing Solutions at The Battery Show Europe

Lead Intelligent Equipment ("LEAD") a global leader in intelligent manufacturing for the new energy sector, made a significant impact at The Battery Show Europe 2025, held June 3–5 in Stuttgart, Germany. The company unveiled its “full value chain + full lifecycle” battery manufacturing technologies—demonstrating how smart automation, AI, and sustainable design are shaping the future of battery production. With battery markets expanding and sustainability goals accelerating, LEAD’s equipment solutions are helping manufacturers meet growing global demand through efficiency, scalability, and environmental responsibility. Integrated Solutions Across the Battery Lifecycle At Booth 10-B20, LEAD presented a comprehensive lineup of advanced technologies supporting every stage of battery production. Key solutions included: Full solid-state…

-

Driving Innovation Together

LEAD Intelligent Equipment proudly hosted a distinguished delegation from Bayern Innovativ at its European Center of Competence in Naila. The visit brought together stakeholders from across Bavaria’s innovation ecosystem for a day of insight, exchange, and collaborative dialogue on the future of mobility and smart manufacturing. A Convergence of Expertise and Vision The delegation included representatives from Bayern Innovativ’s Automotive Cluster and other innovation areas. Through guided tours, thematic presentations, and interactive breakout sessions, we explored a range of forward-looking topics—e-mobility, connected vehicle systems, automation, digital manufacturing, and sustainable supply chains. The event reflected not only LEAD’s innovation-driven mission but also the broader momentum behind Bavaria’s strategic transformation efforts. A Broader Framework:…

-

Lead Intelligent Equipment Signs Major Contract with FAAM to Deliver Advanced End-of-Line Lithium Battery Production Solution for 8 GWh Facility in Italy

Lead Intelligent Equipment ("LEAD"), a global leader in smart manufacturing solutions for lithium-ion batteries, is proud to announce the signing of a major contract with FAAM – Energy Saving Battery, a subsidiary of Seri Industrial S.p.A., to provide a state-of-the-art end-of-line (EOL) solution for FAAM’s new Teverola 2 facility near Naples, Italy. The Teverola 2 plant will feature multiple high-efficiency lithium iron phosphate (LFP) battery production lines and is expected to reach a total annual production capacity of 8 gigawatt-hours (GWh). The new facility will play a pivotal role in advancing Europe’s battery manufacturing capabilities and supporting the EU’s green energy transition and sustainability goals. Scope of the Project LEAD’s…

-

LEAD Intelligent Equipment Showcases Innovation and Industry Expertise at The Battery Show Middle East

Lead Intelligent Equipment ("LEAD"), a global provider of smart manufacturing solutions for battery production, made a strong impression at The Battery Show Middle East by contributing technical insights and strategic perspectives that are shaping the next era of battery manufacturing. A central voice in LEAD’s presence at the event was Dr. Hannes Weinmann, Head of the International Technical Center at LEAD Germany, who delivered a compelling keynote presentation and participated in a high-level panel discussion—sharing firsthand knowledge from years of hands-on experience in scaling gigafactory production. Leading Conversations Around Smart Manufacturing In his keynote, titled “Accelerating Factory Ramp-Up and Enhancing Production Efficiency with Innovative Manufacturing Solutions,” Dr. Weinmann outlined practical…

-

AI-Powered Welding Inspection: Lead Intelligent Equipment Enhances Battery Quality with Precision

Lead Intelligent Equipment ("LEAD"), a pioneer in intelligent automation and AI solutions for manufacturing, has successfully deployed its advanced AI-powered welding inspection technology, significantly enhancing battery quality control for battery manufacturers. Leveraging over 20 years of experience in lithium battery manufacturing, LEAD has developed an innovative AI welding discrimination model capable of adapting to complex production environments and accurately identifying welding anomalies in real-time. This breakthrough addresses critical pain points in the battery manufacturing sector, particularly ultrasonic welding, where traditional inspection methods face significant limitations. About the Customer The customer is a leading enterprise in new energy, recognized for its robust technical capabilities, large-scale production facilities, extensive customer network, and…

-

LEAD Successfully Delivers 100MW Perovskite Coating Machine, Driving Industry Advancement

Lead Intelligent Equipment (LEAD), a global leader in intelligent manufacturing solutions, has successfully developed and delivered a 100MW perovskite coating machine for a leading Chinese perovskite solar cell manufacturer. This cutting-edge equipment has facilitated the successful launch of multiple new products, reinforcing LEAD’s position at the forefront of the renewable energy industry. Proprietary Technology Enhancing Equipment Performance The newly developed 100MW perovskite photovoltaic pilot line is among the first of its kind in China, integrating LEAD’s proprietary large-width perovskite planar coating system. Designed for slot-die coating of perovskite layers, modification layers, and other functional components in perovskite production and pilot lines, this system incorporates several groundbreaking technologies, including: Dual-drive gantry…

-

LEAD Partners with a Leading South Korean Enterprise to Set a New Benchmark in Enhancing Accuracy for Digital Lithium-Ion Battery Manufacturing

Lead Intelligent Equipment (LEAD) has entered into a strategic partnership with a prominent South Korean enterprise to provide state-of-the-art cutting and stacking equipment for their high-end digital battery cell production line. This collaboration delivers a cutting-edge integrated solution, significantly enhancing manufacturing accuracy and setting a new industry standard. The partnership marks a pivotal breakthrough for LEAD in the digital manufacturing sector, solidifying its position at the forefront of technological innovation in lithium-ion battery production. The South Korean client is a globally renowned battery manufacturer with a substantial market share in both the electric vehicle (EV) and digital battery sectors. It is a key supplier to several world-class automotive and digital…