-

Montech Conveyors Corp. launches a new aluminum framing system

Montech Conveyors Corp. expands its product portfolio by adding a new advanced aluminum framing system, featuring four types of profile groups and a wide-ranging line of accessories. Besides the tried and proven dovetail clamping technology, now we also offer dovetail slot connection technology and clamping technology – the disruptive geometry of the dovetail sliding nut permits precise and secure clamping. The new aluminum framing system MPS from Montech is an expansion of the successful Quick-Set aluminum system profile, which we will continue to offer. Its combination of dovetail clamping and dovetail slot connection system is unique: it enables precise and secure clamping and fastening of components and accessories to the…

-

Efficient solution for transporting oily and coated parts

Cleanliness is a top priority in the production processes of metalworking plants that handle oily or cooling emulsion-coated, sharp-edged parts. On the one hand, dirt and oil are annoying; on the other hand, they are also dangerous. If oily parts drop onto the floor, they soil the workplace and cause a risk of slipping. Conveyor lines that enable clean production processes are therefore mandatory. Belt conveyor with swiveling drive Montech offers solutions for clean and energy-efficient processes. The company specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems. Its TB30 belt conveyor is characterized by a swiveling head drive. Because it…

-

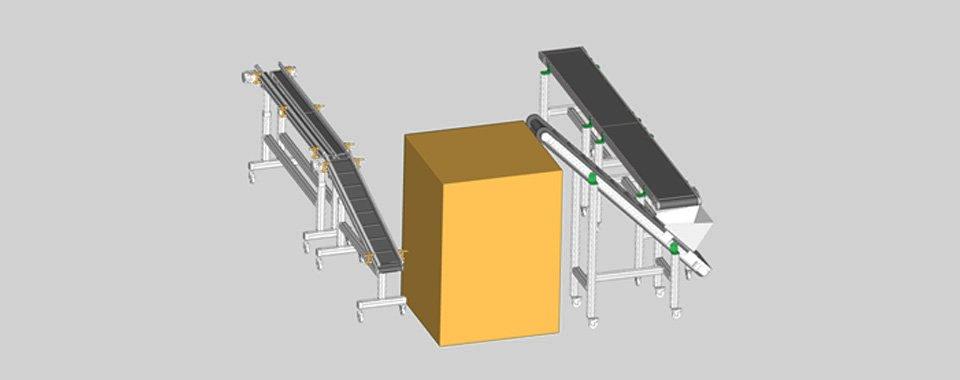

About the benefits of automated, flexible production

Montech AG is a Swiss technology company that specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems. With its expertise and experience, it implemented exactly the solution this dry ice producer had been seeking. The solution needed to compensate for the different discharge and working heights of the various machines and be mobile. By simply moving the individual belt conveyors, they can be used where and when they are needed. It was also important to consider how to integrate a possibility for sawing up ice blocks. Optimized, resource-sparing work process With a total of five belt conveyors – two TB40s and…