Economical deburring and cleaning in one process

More stringent requirements for particulate cleanliness result in higher demands on component cleaning and deburring. This applies in particular to machined components such as components for hydraulic and pneumatic systems, housing components, nozzles, components for gears, motors, steering and brakes. Workpieces for medical technology applications can also be affected. In order to achieve the required cleanliness specifications in a stable manner, cleaning the workpieces alone is usually no longer sufficient. This is because not removed burrs and chips and they are not removed during cleaning can become detached in subsequent processes and re-contaminate the component. Reliable deburring of the components is therefore a must in order to meet particulate cleanliness requirements in a stable and economical manner.

Designed for maximum flexibility and precision

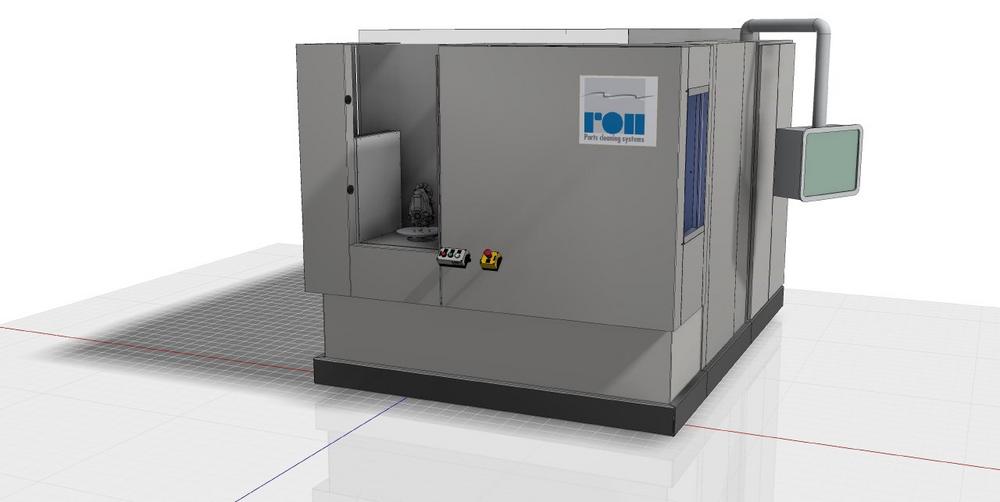

Deburring machined components is a challenge due to areas that are difficult to access, such as internal and intersecting holes, deep and small holes, undercuts and blind holes. Karl Roll GmbH has developed the FlexJet HD series for these tasks. The highly flexible and efficient high-pressure water jet deburring system enables deburring and cleaning with a water pressure of around 500 bar in one work step. The rotary table integrated in the treatment chamber of the new system with pneumatic connections for automatic workpiece clamping devices is designed for components with a diameter of up to 450 mm and a maximum height of 550 mm. The maximum workpiece weight including the clamping device is 100 kg. These dimensions make it possible to handle, for example, an engine block for a four-cylinder engine or several small parts. The water jet generated in the high-pressure unit with a pressure of up to 500 bar is passed through a four-way nozzle system with automatic nozzle switch. For a precise and reproducible result, the workpiece can be rotated during the process as required and moved along the X-axis. At the same time, the nozzles can be moved along the Y and Z axes. This possibility of very targeted processing not only reliably removes adhering chips from areas that are difficult to access, such as transverse and deep hole bores, but also detaches and removes clamping chips, welding beads and layers of scale. The system thus ensures optimal results even with geometries and contamination where classic processes reach their limits. The water jet can be directed flat for deburring and cleaning larger surfaces. The high kinetic energy also removes stubborn contamination such as sweat residues and silicates.

Simple programming through modern control technology

State-of-the-art control technology is used to position the CNC axes, which are also used in machine tools. The process sequence can be programmed offline using G-code and a teach-in solution via a 15 inch control panel. There is also the option of programming with a handheld terminal via teach-in. These solutions enable simple and fast programming of the contours to be followed as well as very exact positioning in the areas to be deburred without special programming knowledge.

Effective media preparation included

The burrs and chips removed during the deburring and cleaning process are reliably removed by an effective filter system consisting of a pre-filter and a fine filter. The process water can therefore be circulated without any problem. In addition, a safety filter is integrated in front of the high pressure pump.

Due to the high variability in workpieces and possible applications, the FlexJet HD enables the increased demands on particulate cleanliness to be met efficiently and stably. The low use of media and energy efficiency also contribute to the high profitability of the new system for high-pressure deburring and cleaning. Tests can be carried out in Karl Roll’s technical center from October 2021.

Karl Roll GmbH & Co. KG

Kanalstrasse 30

75417 Mühlacker-Enzberg

Telefon: +49 (7041) 802-0

Telefax: +49 (7041) 802-113

http://www.roll-reinigungssysteme.de

SCHULZ. PRESSE. TEXT

Telefon: +49 (711) 854085

E-Mail: ds@pressetextschulz.de

![]()