SPE – seamless and sustainable end-to-end connectivity

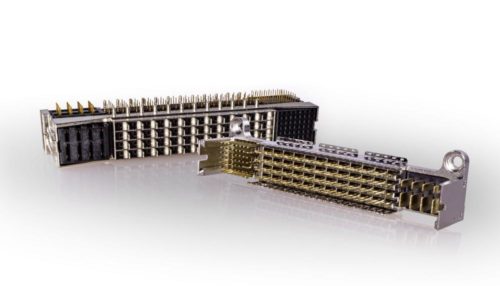

binder, a leading supplier of industrial circular connectors, develops robust and economical connectivity solutions for use in Single-Pair Ethernet (SPE). The miniaturized industrial connectors of the 808 series are equipped with screw locking. They support the transmission of data and electrical power in future-proof automation solutions according to the SPE standard. Thanks to the established and compact M8 design, the connectors can be beneficially integrated into standard sensor technology housings.

Ethernet in factory and process automation

Industrial automation technology is transitioning from hierarchical to decentralized architectures that offer higher productivity and more security for manufacturing companies‘ networks. Decentralization is increasing the number of connected devices in the field, which also creates a greater need for interfaces. Decentralized automation components, i.e. sensors, actuators, controllers, gateways, and embedded or edge computers, are subject to strict requirements in terms of miniaturization and, particularly important at the present time, energy efficiency. In terms of electrical connection technology, this is being mirrored in design criteria such as compact construction, mechanical ruggedness, reliability, and signal integrity.

Another feature of future manufacturing solutions is end-to-end communication: As Industrie 4.0 advances, Industrial Ethernet is penetrating traditional automation levels and ensuring seamless end-to-end data transmission from the field-level sensor through the control and operating levels to the cloud. This continuity enables users to access real-time device data in addition to process data and use it for production planning, process control and data analysis.

SPE: focus on cost and resources

On the one hand, digitization, decentralization and seamless end-to-end data transmission drive the demand for connectors in the automation market; on the other hand, they sharpen the requirements on product functionality and properties. The cost-effectiveness of the connectivity solutions, measured both in terms of the materials and energy required and the installation effort, is coming into even greater focus than before. Single-Pair Ethernet allows high-performance and particularly cost-effective wiring of field components using only one twin wire. The technology thus stands for cost-effective, sustainable networking.

The wiring method already established in automotive engineering has the potential to meet the requirements of many applications in industrial automation as well: Depending on the distance, devices with gigabit transmission rates can be integrated into Ethernet networks via the single pair of wires. Power over Data Line (PoDL) can be used to supply power to the instrumentation via the same pair of wires. In addition to sensors and actuators – in the power range of the previous Power over Ethernet (PoE) – camera-based systems for test and measurement can also be connected and supplied via PoDL, for example.

Dieter Sandula, Product Manager at binder, comments: "SPE will undoubtedly make its way into the existing data infrastructure. This type of data transmission can lead to more sustainable systems that improve cost-effectiveness in automation. In addition, reduced consumption of resources in manufacturing and processing ultimately brings an environmentally sustainable advantage."

Product design according to IEC standard

binder is currently developing products to meet IEC standards 63171-5 and 63171-6 for Single-Pair Ethernet. The standards define the physical dimensions as well as the mechanical, electrical and transmission characteristics; also the environmental requirements, test specifications, and mating faces for SPE data transmission. They cover both shielded and unshielded connectors, which must be designed to interoperate and be interchangeable in terms of their internal transmission performance.

The current product development at binder is based on two base technologies: on the one hand, power supply via PoDL, and on the other hand, a hybrid concept that provides separate data and power transmission. Accordingly, the new SPE products of the 808 series are 2- and 4-pin M8 connectors as well as the respective mating device connectors according to IEC 63171-5 and IEC 63171-6, respectively. The field-wireable connectors are intended for flexible termination directly in the field and will be available from 2023.

binder, headquartered in Neckarsulm, Germany, is a family-owned company shaped by traditional values and one of the leading specialists for circular connectors. Since 1960, binder has been synonymous with the highest quality. The binder group includes the binder headquarters, nine sales offices, seven production sites, two system service providers as well as an innovation and technology center. The company works with further distribution partners on six continents and employs around 2,000 people worldwide. In addition to Germany, the binder sites are located in Austria, China, France, Hungary, the Netherlands, Singapore, Sweden, Switzerland, the UK, and the USA.

Franz Binder GmbH & Co. Elektrische Bauelemente KG

Rötelstraße 27

74172 Neckarsulm

Telefon: +49 (7132) 325-0

Telefax: +49 (7132) 325-150

http://www.binder-connector.de

Category Leader Brand Communication

Telefon: +49 (7132) 325-448

Fax: +49 (7132) 325-150

E-Mail: p.heckler@binder-connector.de

![]()