BEST LINE systems from BST set new standards in quality assurance

When maximum quality is the goal, "very good" performance is insufficient; this is where the BST products of the BEST LINE series come in: The high-precision quality assurance systems FRAMEGuide Pro, regi star 20 Pro, iPQ-Check Pro, and TubeScan Pro enable performance that far exceeds industry-defined benchmarks thanks to enhanced functions. The intelligent, new key features ensure even greater control and inspection accuracy in the Pro models of the established BST systems, ensuring flawless precision in web processing production processes across industries.

FRAMEGuide Pro: Revolution in high-precision applications

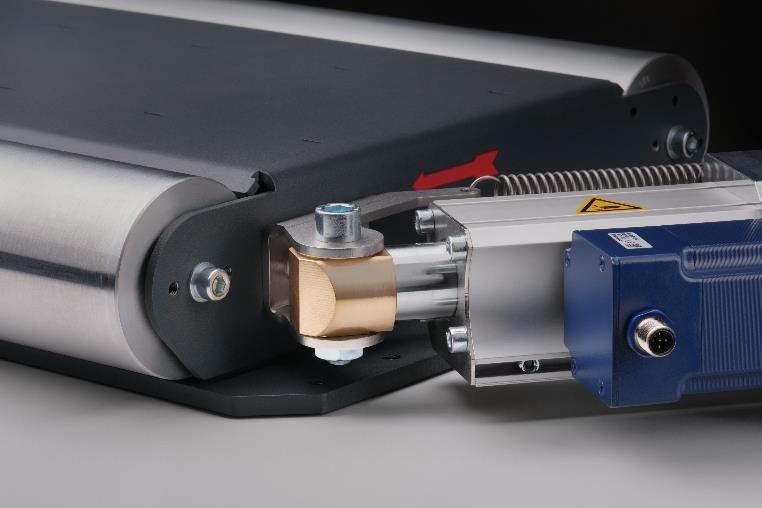

The highlight of the FRAMEGuide Pro web guiding system is the newly developed high-performance drive: With repeat accuracies of ±10 μm, it ensures highly precise control results in every application – an invaluable advantage in applications requiring maximum precision, such as in battery and fuel cell production or the pharmaceutical industry. The compact FRAMEGuide Pro can be optimally and flexibly integrated into all machine layouts due to its lowest possible overall height, with fixed and moving frames arranged at the same level.

Optional motorized sensor adjustment adds flexibility and ensures maximum efficiency in web guiding.

regi_star 20 Pro: Maximum measuring accuracy with RSC matrix camera sensor

The second high-performance star in the BEST LINE has been specially developed to produce safety and function-relevant end products in the organic, photovoltaic and printed electronics industries. With its high-precision scanning and control algorithms, the high-resolution RSC matrix camera sensor regi_star 20 Pro detects even minimal deviations in the smallest dot mark fields, enabling ultra-precise measurement accuracy of up to 2 μm. In conjunction with the FRAMEGuide Pro, regi star 20 Pro provides unrivaled control comfort and precision at the highest level for every measurement, allowing users to significantly optimize their production processes immediately and in the long-term.

iPQ-Check Pro: Print defect detection at high speeds

The BST iPQ-Check Pro high-precision system is one of the printing industry’s leading inspection systems, providing maximum precision in print defect detection even at high speeds and very wide webs. With a maximum resolution of up to 16 K, it inspects web widths of up to 2.90 m. The detectable print defect size is 0.02 mm², and this quality standard is guaranteed even at web speeds of 600 meters per minute. Like the standard iPQ-Check model, iPQ-Check Pro can be easily integrated into any machine due to its extremely compact design. As a smart tool for quality management, iPQ-Check Pro combines uncompromising print image inspection with high-precision web monitoring across the entire print format, thus sustainably improving print quality.

TubeScan Pro: High-Precision Inspection System for Flawless Print Quality

TubeScan Pro is another high-speed talent in the field of print inspection: the innovative inspection system of the BEST LINE provides maximum performance when used in cutting and converting machines for packaging printing and labels, and detects defects even faster and more reliably. Even with web widths of up to 550 mm and speeds of up to 500 meters per minute, high precision is maintained with resolutions of up to 0.1 mm. The integrated press control system actively positions detected errors at the target position for error correction, ensuring perfect print quality while reducing waste. For optimum cooperation with the press, TubeScan Pro can be integrated precisely into the SMARTData workflow.

BST GmbH, a company of the elexis group of companies, is one of the leading suppliers of quality assurance systems for web processing industries. Based in Bielefeld, Germany, the company offers solutions for web guiding, surface inspection, web inspection, 100% inspection, color measurement, color management, register control and automation. In these areas, the company has decades of practical know-how with installations at more than 15,000 customers worldwide in the printing and packaging, paper and film, rubber and tire, battery and fuel cell, and printed and organic electronics industries. BST stands for high quality monitoring, smooth production processes and first-class service worldwide.

[url=https://www.elexis.group/en/]www.bst.elexis.group[/url]

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Head of Corporate Communications

Telefon: +492762612286

E-Mail: Konrad.huenerfeld@elexis.de

![]()