“Make the difference” – is the motto of this year’s Hannover Trade Show from April 17 to April 21.

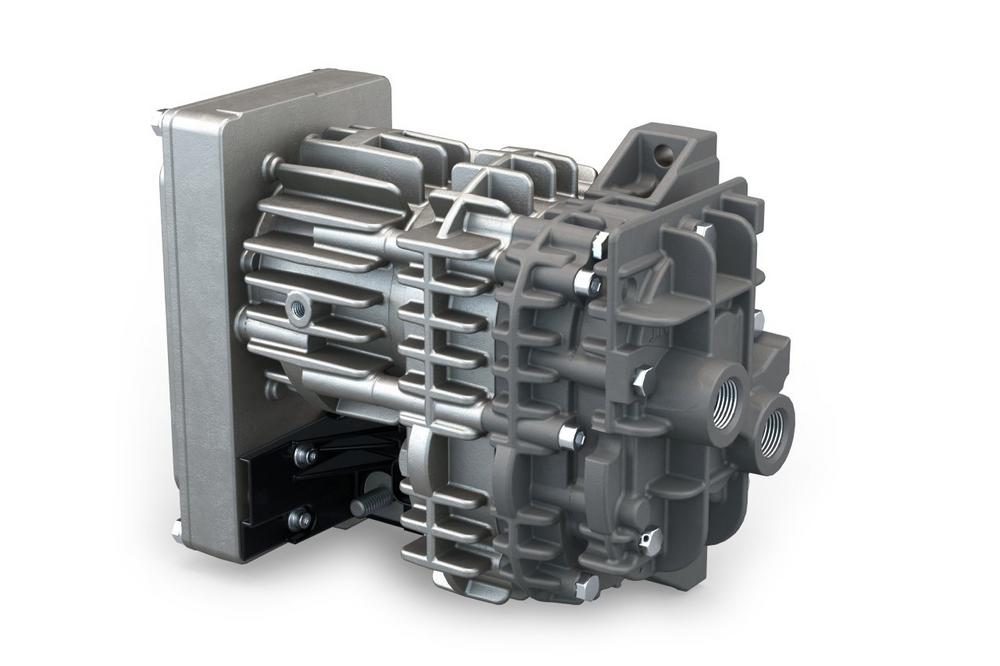

The recirculation blower MINK MH 0018 A ensures optimal recirculation of hydrogen within fuel cells with an output of up to 45 kilowatts. The blower can also be used at a lower recirculation rate for fuel cells with up to 60 kilowatts. For bigger fuel cells, it is possible to operate several blowers at the same time. Due to its small dimensions, the MINK hydrogen recirculation blower can be directly installed into the fuel cell module.

Busch’s pioneering vacuum solutions make the difference

The new blower features an intelligent variable speed drive. This makes it possible to automatically adjust the volume flow to the actual fuel cell requirements. Thus achieving the greatest possible efficiency. The MINK hydrogen recirculation blower can easily be operated at hydrogen temperatures between -30 to +85 °C and ambient temperatures ranging from -30 to +95 °C. Thus it is suitable for automotive applications in vehicles and for stationary fuel cell modules.

The hydrogen recirculation blower operates according to the proven claw principle. Compression is completely oil- and contact-free. Two claw-shaped rotors rotate in opposite directions inside a housing. Due to the shape of the claw rotors, the already pre-compressed hydrogen is suctioned in and compressed up to 0.4 hPa (mbar) further and fed back into the hydrogen supply before the anode. Small clearances between the claw rotors and the housing optimize the inner seal. A special coating of all parts exposed to hydrogen prevents corrosion due to the deionized water vapor that is also conveyed. A synchronized gearbox maintains precise rotor timing. It is lifetime-lubricated by a special oil. No oil change or other maintenance work is required.

It is not only the TÜV that has extensively tested and approved the hydrogen recirculation blower MINK MH 0018 A from Busch. Fuel cells with this blower have already been installed in over 2,000 public buses in Shanghai.

Meet with Busch vacuum experts to personally exchange information at Hydrogen + Fuel Cells EUROPE in Hall 13, Booth B16!

Busch Vacuum Solutions is one of the world’s largest manufacturers of vacuum pumps, vacuum systems, blowers and compressors.

The extensive product portfolio includes solutions for vacuum and overpressure applications in all industries, such as chemicals, plastics, semiconductors, medical technology and food. This also includes the design and construction of tailor-made vacuum systems and a worldwide service network.

The Busch Group is a family business that is managed by the Busch family. More than 3,800 employees in more than 69 companies in over 45 countries worldwide work for Busch Vacuum Solutions. Busch is headquartered in Maulburg, Baden-Württemberg, in the border triangle of Germany – France – Switzerland. Apart from Maulburg, Busch manufactures in its own production plants in Switzerland, the USA, Great Britain, the Czech Republic, South Korea, India and China.

Busch Vacuum Solutions

Schauinslandstraße 1

79689 Maulburg

Telefon: +49 (7622) 681-0

Telefax: +49 (7622) 5484

http://www.buschvacuum.com

E-Mail: sabrina.heinecke@busch.de

![]()