Artificial intelligence and robotics – the key to sustainable battery recycling?

The LAMBDA research project

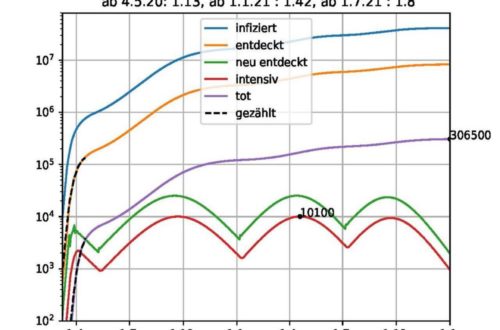

The aim of the project is to develop a pipeline for the automatic training of robots for the disassembly of electric vehicle batteries using state-of-the-art AI techniques. "First, we will construct digital replicas of batteries that provide a high-quality simulation," explains Dr Özhan Özen, Data Scientist at the Swiss Battery Technolgy Center. "Using computer vision and machine learning, the robots in the simulation will acquire manipulation skills, such as unscrewing, suitable for different battery architectures." This is possible even if the batteries are damaged. These skills are then refined and tested with real robots during the disassembly of real battery components in an industrial production environment.

Research expertise from two countries and three organisations

The project aims to develop a novel pipeline that teaches industrial robots advanced manipulation techniques for the automatic disassembly of batteries. Each member of the consortium brings unique expertise that can complement the know-how of the other members.

Startup Circu Li-ion

Circu Li-ion is a European battery upcycling company. Their mission is to save the planet by boosting the value of each battery. In 2021, they embarked on their journey to revolutionize the battery value chain by automating and scaling the disassembly of batteries and the diagnostic of cells – for a more economical and ecological battery recycling. They provide a technology to leading players in the space of electric vehicles, micro-mobility, power tools, energy storage systems, and recycling. Their Machine-as-a-Service solution offers the possibility to give used batteries a second life through upcycling instead of recycling – saving money and the planet.

Startup AICA

AICA SA is the main implementation partner. This Swiss startup is a robotic and machine-learning technology-oriented company, with proven experience in project management and commercialization. AICA SA was founded in the renowned LASA laboratory at EPFL under the direction of Professor Aude Billard and has already received more than CHF 1.5 million funding from Schaeffler VC, Spicehaus Partners, Hightech Gründerfonds, Innosuisse, Venture Kick, Innogrant, and Innoboster. As a flagship product, the company has developed an adaptive force-fit assembly process for automotive planetary gearboxes, from its concept to the production-ready solution.

Swiss Battery Technology Center (SBTC): The SBTC is one of four research centers of the Switzerland Innovation Park Biel/Bienne (SIPBB). The Switzerland Innovation Park Biel/Bienne is a private Swiss non-profit organization that conducts and supports industry-oriented and primarily applied research and development. The SBTC conducts research in the areas of battery ageing, battery applications and battery disassembly. At the SIPBB, a research laboratory for automatic battery disassembly and recycling of lithium-ion batteries is being built that is unique in Switzerland.

Eurostars: Support for research in SMEs

Eurostars is aimed at innovative small and medium-sized enterprises, i.e. those that develop processes or products that differ significantly from their previous activity. Thanks to Eurostars, SMEs can collaborate with the research teams of the most appropriate partner countries of the programme and strengthen their competitiveness in the field of know-how and innovation. All thematic areas are eligible. Calls for innovative projects are regularly published on the Eureka website.

The LAMBDA project is also supported by:

In Switzerland: Innosuisse – Swiss Innovation Agency

In Luxembourg: Luxinnovation

Switzerland Innovation Park Biel/Bienne AG

Aarbergstrasse 46

2503 Biel/Bienne

Telefon: +41 (32) 53088-88

http://sipbb.ch

Head of Swiss Battery Technology Center at Switzerland Innovation Park Biel/Bienne

Telefon: +49 (79) 40395-86

E-Mail: christian.ochsenbein@sipbb.ch

COO, Head of PR at Switzerland Innovation Park Biel/Bienne

Telefon: +49 (78) 84782-61

E-Mail: anita.joerg@sipbb.ch

![]()