Softing Launches Enhanced Siemens Connector for tManager® To Simplify Direct PLC-to-Database Integration

Simplified integration via the Siemens Connector

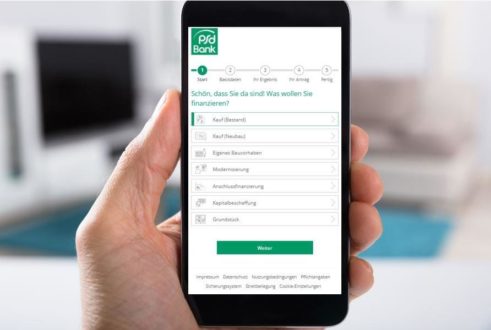

The enhanced Siemens connector builds on Softing’s proven tManager in-chassis connectivity platform and expands tManager ControlLogix and tManager IPC (Industrial PC) to support Siemens controllers in addition to Rockwell and Modbus PLCs. Users can now browse PLC symbols and SQL database fields directly, set up triggers and deploy industrial applications such as track and trace, quality monitoring, KPI dashboards and recipe downloads.

Symbol browsing speeds up project realization

Previously, Siemens integration required time-consuming, manual symbol setup. With this new functionality, browsing and mapping symbols from Siemens S7 1200 and 1500 controllers is now just as streamlined as it is with Rockwell PLCs. The update also maintains support for legacy symbol creation with Siemens S7 300, 400, 1200 and 1500 controllers, ensuring full backward compatibility for existing installations.

tManager drives digital transformation

“tManager is a unique digital transformation enabler. It’s designed to bridge PLCs and databases without requiring expertise in both,” said Deane Horn, Director of Product Management at Softing Inc. “This update makes Siemens integration faster and far less error-prone. We’ve eliminated a tedious, manual step by enabling symbol browsing — a big leap for productivity and project scalability.”

Meeting Today’s Industrial Challenges

As manufacturers face increasing pressure to improve traceability, reduce errors and gain real-time insights from plant-floor data, legacy approaches like clipboard logging or custom-coded solutions often fall short. tManager addresses these challenges with a no-code, off-the-shelf solution that’s easy to deploy and maintain.

Reliable, Scalable Integration Without Coding

With robust in-chassis and IPC-based architecture, built-in fault tolerance, store-and-forward capabilities and scalable integration with multiple PLCs and databases, the solution offers a reliable and supportable path to digital transformation.

It enables rapid implementation of high-value industrial use cases including KPI monitoring, high-speed sorting, recipe management and MES integration — without the complexity of OPC protocol translation or PC-based middleware.

Softing connects disparate automation components to feed data from the shop floor to the cloud for control and analytics. The company’s products enable communications networks to be monitored and diagnosed to ensure a reliable flow of data, thereby creating the basis for optimizing production processes. For more information, please visit https://industrial.softing.com

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar bei München

Telefon: +49 (89) 45656-0

Telefax: +49 (89) 45656-488

https://industrial.softing.com/index.html

Marketing Communications Specialist

Telefon: +49 (89) 45656-365

Fax: +49 (89) 45656-399

E-Mail: stephanie.widder@softing.com

![]()