Continuous monitoring of bridges and buildings with the right sensors

There are many ways in which sensors can support bridge / bulding monitoring:

- Early detection of structural problems: Damage such as cracks should be detected at an early stage by analyzing the measurement data in order to initiate appropriate countermeasures.

- Traffic monitoring: They enable the analysis of traffic load peaks in order to check whether the bridge can withstand the loads or whether repairs are required.

- Long-term monitoring: Continuous monitoring allows changes in vibration behavior to be detected over time, indicating wear or incipient damage.

- Real-time alerting: Modern coupled systems can sound the alarm immediately in the event of critical changes, enabling rapid response measures.

- Preventive maintenance: The collected data helps to carry out maintenance work in a targeted and efficient manner before serious damage or failures occur.

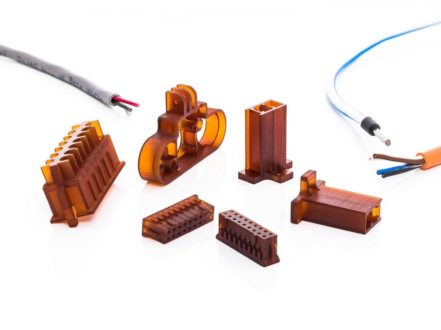

disynet GmbH has a large portfolio of various special sensors for structural health monitoring (SHM):

- Vibration sensors record vibration patterns of the bridge. Abnormalities in vibration behavior can indicate cracks, corrosion, loosening or other damage.

- Movement analysis and posture monitoring: inclination sensors measure the alignment and position of the body, especially the back. They can record how often and for how long a person adopts an incorrect posture, e.g. leaning forward too much when sitting or lifting.

- Linear potentiometers measure linear movements or displacements in a fixed direction. They convert a mechanical displacement into an electrical resistance. They are used to detect deformations or displacements in bridge sections. If the bridge deforms slightly due to traffic, temperature changes or loads, linear potentiometers can measure these displacements accurately.

- Draw-wire sensors are used to monitor strains or tensile stresses in ropes, cables or supporting structures. They are installed on load-bearing cables or struts to detect changes in tension that may indicate overloading, material fatigue or the development of damage.

- As part of load monitoring, pressure sensors measure the forces acting on the bridge, e.g. from vehicle traffic or wind loads. This allows the actual load to be compared with the planning assumptions. Through continuous measurements, pressure sensors can detect structural changes in the pressure curve that indicate material fatigue, cracks or other structural damage.

- Force sensors measure forces at specific critical points, providing information about load distribution, stresses, and possible signs of fatigue. Continuous measurements give engineers a clear picture of the dynamics of the structure under wind, traffic, temperature changes, or earthquake loads. Force sensors also provide important data for validating calculation models, thereby contributing to the long-term service life and reliability of large structures.

- Laser distance sensors enable contactless, precise measurements of distances to surfaces from a safe distance, even over long distances. This allows deformations, distortions, or displacements to be continuously monitored without affecting the structure or requiring work equipment. The advantages lie in high measurement accuracy, speed, and the ability to deliver data in real time. This allows early warning signals for material degradation, settlement, or component failure to be detected at an early stage. In combination with sensor networks, data logic, and visual representation, laser distance sensors support maintenance, condition monitoring, and safety management.

Learn more about our monitoring sensors or receive individual application advice from our specialists: marketing@disynet.de

You can find a small selection of these sensors at:

https://www.sensoren.de/anwendungen/zustandsueberwachung/monitoring-sensoren/

For further information visit our web site: www.sensors.de

For sensor know-how, visit our online sensor compendium www.sensoren.info (in German)

Die disynet GmbH ist Ihr kompetenter Partner für innovative Sensor- und Messtechniklösungen. Seit unserer Gründung im Jahr 1995 bieten wir maßgeschneiderte Konzepte für die speziellen Anforderungen unserer Kunden an. Unter unserem Motto „MADE TO MEASURE“ verstehen wir es, individuelle Lösungen zu entwickeln, die sowohl Verpflichtung als auch wertvolles Kapital für unsere Kunden darstellen.

Unser umfassendes Produktspektrum beinhaltet eine Vielzahl von Messwertaufnehmern und Messtechniksystemen, die unterschiedliche Messgrößen abdecken und auf verschiedenen Sensortechnologien basieren. Wir bieten u.a. hochpräzise Sensoren wie Beschleunigungssensoren, Drucksensoren, Kraftsensoren, Drehmomentsensoren, Wegsensoren und Neigungssensoren an.

Unsere Produkte finden vielseitige Anwendung in den Bereichen „Test & Measurement“, Prüfstandsmessung, Forschung und Entwicklung sowie Zustandsüberwachung. Dabei bedienen wir diverse Industrien, darunter die Automobilindustrie, Luft- und Raumfahrt, Schiene und Bahn, Windkraftanlagen, Landmaschinen sowie Bauwerke. Die disynet GmbH steht für Qualität, Innovation und Kundenorientierung – für jede Herausforderung die passende Lösung.

disynet GmbH

Breyeller Str. 2a

41379 Brüggen-Bracht

Telefon: +49 (2157) 8799-0

Telefax: +49 (2157) 8799-22

http://www.sensoren.de

Head of marketing

Telefon: +49 (2157) 8799-28

Fax: +49 (2157) 8799-22

E-Mail: marketing@disynet.de

![]()