Boix brings the HAT MINI to LogiMAT: compact lidding automation for faster, more efficient packaging operations

Hall 6, Stand 6A77

Rising pressure on costs, labour availability and delivery performance is pushing companies across supply chain and e-commerce to rethink packaging processes. With the HAT MINI, Boix introduces a compact hot-melt lidding machine designed to automate one of the most underestimated steps on the packaging line: folding, gluing and closing cardboard lids directly in-line.

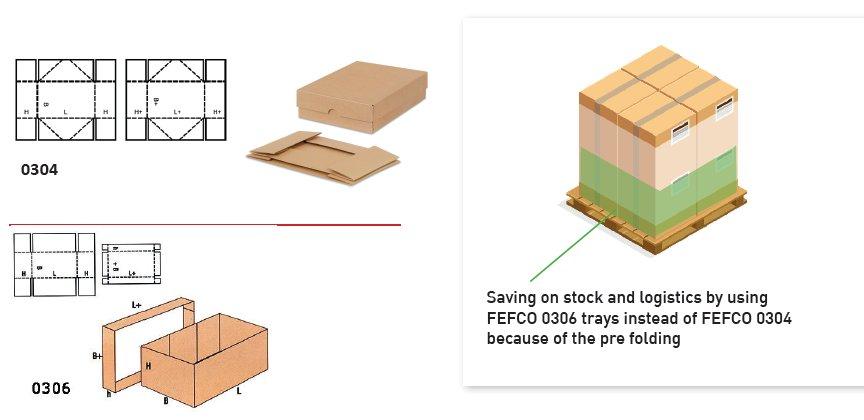

The HAT MINI forms lids from flat blanks, applies hot-melt glue and closes the box automatically. By replacing pre-folded lids with blanks, companies can significantly reduce storage volume, improve internal logistics and streamline throughput, while maintaining reliable sealing quality.

Less storage, less handling, more efficiency

Many operations still rely on pre-folded lids, which are familiar but inefficient from an intralogistics perspective. Pre-folded lids require considerable warehouse space, create extra pallet movements and add manual handling to the line. Flat blanks, on the other hand, are delivered compactly and can be processed automatically in the packaging line. This reduces the number of pallets in storage, lowers transport and handling requirements and supports higher material density per shipment — an advantage that becomes particularly relevant during seasonal peaks or high-demand periods.

Compact automation for modern packaging and fulfilment environments

The Boix HAT MINI has been developed for businesses that want to automate lidding with minimal footprint and easy integration. The machine reaches speeds of up to 1,300 lids per hour, making it suitable for both continuous production and peak-period output requirements. A 1.5-metre blank storage capacity increases line autonomy and reduces operator intervention, while servo-driven controls ensure repeatable movement and accurate lid placement. Glue parameters can be adjusted directly via the touchscreen, enabling operators to optimise sealing performance for different cardboard qualities and transport requirements. The machine supports common box types such as Bliss boxes and C-1 trays, offering flexibility for lines handling multiple SKUs or changing packaging formats.

Designed for multiple industries

While compact lidding solutions are widely used in fresh produce environments, Boix positions the HAT MINI as a versatile automation step for a broad range of industries that rely on secure packaging and fast throughput, including:

• E-commerce and fulfilment

• Food and fresh supply chains

• Meat and protein packaging

• Cosmetics and personal care

• Wineries and specialty goods

• General distribution and retail-ready packaging

This makes the HAT MINI a practical choice for companies looking to standardise packaging quality, reduce manual work and improve packaging efficiency across different product flows.

Part of a broader portfolio of packaging automation solutions

The HAT MINI is one of several packaging solutions offered by Boix. With a long track record in box forming and closing machinery, Boix provides scalable automation options to support businesses ranging from compact production facilities to high-volume operations.

Visit Boix at LogiMAT

Boix will showcase the HAT MINI at LogiMAT 2026 in Stuttgart. Visitors can explore how compact lidding automation can reduce storage and transport volume, simplify packaging workflows and improve operational efficiency in intralogistics and fulfilment environments.

24–26 March | Stuttgart Trade Fair Centre

Hall 6 – Stand 6A77

For more information or to book a meeting during the show:

sales@boixeurope.com | +31 (0)313 670 460 | www.boix.com

Boix Europe B.V.

Loubergweg 6

NL6961 EK Eerbeek

Telefon: +31 (313) 670460

https://www.boix.com

Marketing & Event Coordinator

Telefon: +31 (313) 670-460

Fax: +31 (6) 8233-1905

E-Mail: sandhia@boixeurope.com

![]()