Laser Vibrometer Market Set to Double by 2036 as Non-Contact Vibration Testing Gains Industrial Priority

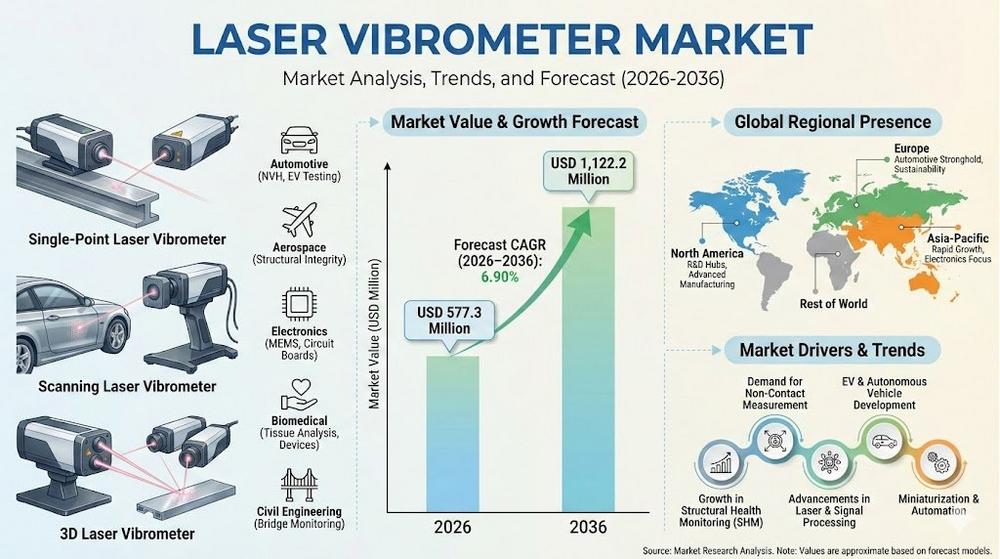

The global laser vibrometer market is entering a phase of sustained, technology-led growth as industries increasingly rely on non-contact vibration measurement for accuracy, safety, and efficiency. Valued at USD 577.3 million in 2026, the market is forecast to reach USD 1,122.2 million by 2036, expanding at a CAGR of 6.90% over the period. This growth reflects rising demand from automotive, aerospace, electronics, and advanced manufacturing sectors that require high-resolution vibration diagnostics without physical contact.

Laser vibrometers use optical principles to measure vibration, velocity, and displacement with extreme precision. Their ability to test delicate, high-speed, or inaccessible components without altering structural behavior has made them a critical tool in modern engineering and quality assurance workflows.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates: https://www.futuremarketinsights.com/reports/sample/rep-gb-30446

Non-Contact Precision Becomes Essential in Advanced Engineering

Industries are facing increasing pressure to improve product reliability, reduce noise and vibration, and meet stricter regulatory standards. Laser vibrometers address these needs by enabling real-time, high-sensitivity vibration analysis in challenging environments.

Key advantages driving adoption include:

- Non-contact measurement that avoids mass loading or signal distortion

- High spatial and frequency resolution for complex structures

- Suitability for fragile, hot, rotating, or moving components

- Compatibility with advanced data analytics and simulation tools

According to industry experts, laser vibrometry has transitioned from a niche research tool to a core diagnostic technology across production, testing, and maintenance applications.

“As mechanical systems become lighter, faster, and more complex, non-contact vibration measurement is no longer optional—it’s essential for design validation and predictive maintenance,” notes a senior vibration analysis specialist from the automotive sector.

Scanning Laser Doppler Vibrometers Lead by Technology

By technology, Scanning Laser Doppler Vibrometers (SLDV) dominate the market with approximately 34% share. These systems enable vibration measurement across thousands of points on a surface, producing detailed vibration maps that are critical for structural dynamics analysis.

SLDVs are widely used in:

- Automotive body and powertrain NVH studies

- Aerospace structural and modal testing

- Research laboratories and advanced material analysis

Their ability to combine speed, coverage, and precision makes them the preferred choice for applications where full-field vibration insight is required.

Automotive NVH Remains the Largest Application Segment

Automotive Noise, Vibration, and Harshness (NVH) testing accounts for nearly 30% of global laser vibrometer demand. Vehicle manufacturers use laser vibrometers extensively to evaluate ride comfort, cabin noise, component durability, and structural integrity.

Laser vibrometers allow engineers to:

- Identify vibration sources without dismantling assemblies

- Optimize chassis, engine, and drivetrain designs

- Validate compliance with regulatory and customer comfort standards

With the rise of electric vehicles, where noise from traditional engines is absent, managing vibration from motors, gearboxes, and lightweight structures has become even more critical, further strengthening demand.

Regional Growth Led by Asia Pacific and China

Asia Pacific and North America remain the most significant growth regions, supported by industrial automation, automotive production, and aerospace investment. China leads country-level growth with a CAGR of 7.9%, driven by rapid industrial expansion and adoption of smart manufacturing technologies.

Other notable country growth trends include:

- Brazil at 7.4%, supported by automotive, aerospace, and renewable energy projects

- USA at 6.7%, fueled by aerospace innovation and quality-driven manufacturing

- South Korea at 6.5%, led by electronics and semiconductor leadership

- Germany at 6.4%, anchored by precision engineering and automotive excellence

Government-backed R&D initiatives and investments in advanced testing infrastructure continue to reinforce regional demand.

Market Dynamics: Innovation, Integration, and Entry Barriers

The laser vibrometer market is characterized by high entry barriers due to significant R&D costs, calibration requirements, and the need for optical and software expertise. Leading players maintain pricing power through technological differentiation and integrated software platforms that deliver actionable insights rather than raw data.

Key market trends include:

- Integration of AI-driven analytics and real-time data processing

- Development of compact and portable systems for field diagnostics

- Multi-modal platforms combining vibration, velocity, and displacement

- Alignment with Industrial IoT and predictive maintenance strategies

While high system costs and the need for skilled operators remain challenges, ongoing innovation is improving usability and expanding the addressable customer base.

Get data that aligns with your strategic priorities — ask for report customization today: https://www.futuremarketinsights.com/customization-available/rep-gb-30446

Competitive Landscape Anchored by Established Measurement Leaders

Competition in the laser vibrometer market centers on measurement accuracy, software capability, ease of integration, and application flexibility. Companies such as Polytec and HBK lead with comprehensive optical measurement portfolios and advanced analysis ecosystems. Other key players including Keyence, Ono Sokki, Dewesoft, Microflown AVISA, Kistler, and Rohde & Schwarz continue to expand their offerings to address both laboratory and industrial requirements.

As industries demand scalable, precise, and easy-to-integrate solutions, the laser vibrometer market is expected to steadily consolidate while maintaining innovation-driven growth through 2036.

Related Reports:

Industrial Valves Market- https://www.futuremarketinsights.com/reports/industrial-valve-market

Micro Irrigation Systems Market- https://www.futuremarketinsights.com/reports/micro-irrigation-systems-market

Pneumatic Actuator Market- https://www.futuremarketinsights.com/reports/pneumatic-actuator-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us – sales@futuremarketinsights.com

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Future Market Insights, Inc

Christiana Corporate, 200 Continental Drive, Suite 401,

USADelaware Newark,

Telefon: +1-347-918-3531

Telefax: +1 845 5795705

http://www.futuremarketinsights.com

Marketing

Telefon: +13479183531

E-Mail: Rahul.Singh@futuremarketinsights.com

![]()