Streamline physical inventory: manage centrally, act locally

The stocktaking software by COSYS offers a smarter way forward: centralized control with local execution. This modern approach combines strategic oversight at headquarters with streamlined execution on-site, ensuring accurate, fast, and cost-effective inventory results—no matter how many locations you manage.

The concept: central control, local execution

The idea is simple: the head office plans and monitors the stocktaking process, while on-site teams perform the counts using mobile devices. This separation of roles not only reduces complexity but also ensures consistency in procedures and data quality.

Instead of relying on emails, Excel spreadsheets, or manually aggregated lists, all planning and monitoring tasks are handled through COSYS’ centralized backend. Meanwhile, local teams receive clear task assignments on mobile scanners or smartphones, allowing them to complete their work efficiently and independently.

This model supports scalable, flexible inventory processes—whether you manage one large warehouse, a nationwide network of stores, or a series of production facilities.

How does the stocktaking software by COSYS work

The stocktaking software is built on a modular system that brings together a web-based control panel and intuitive mobile applications.

At the central level, inventory managers use the COSYS WebDesk to:

- Define inventory periods

- Assign tasks to individual sites or teams

- Monitor progress in real time

- Analyze results and discrepancies

On-site, local staff use Android-based mobile devices—either professional scanners (like Zebra TC21/TC26 or Honeywell EDA52) or standard smartphones. The COSYS mobile app guides them step-by-step through the inventory process:

- Scanning items via barcode

- Entering quantities

- Resolving errors or mismatches on the spot

All data is synced automatically between the devices and the central system via Wi-Fi or mobile data. Even if a site has no reliable internet, offline functionality ensures nothing is lost.

Key features & benefits

The COSYS solution stands out for its blend of control, flexibility, and user-friendliness. Key advantages include:

- Centralized planning and real-time visibility

Inventory management staff can oversee the entire process from a single platform. They can track completion rates, identify delays, and react quickly to issues as they arise. - Accurate and consistent data

Mobile data capture eliminates manual errors common with paper-based methods. Standardized processes across sites ensure data comparability and audit compliance. - Faster execution with local autonomy

Site teams receive clear instructions via the app and can work at their own pace without constantly checking in with central teams. This reduces delays and empowers local staff. - Offline capability

No need to worry about Wi-Fi coverage. COSYS apps can work fully offline, syncing data once a connection is re-established. - Scalable for any company size

From small companies with a single site to large enterprises with 100+ locations, COSYS adapts to your infrastructure and workflows. - Seamless integration

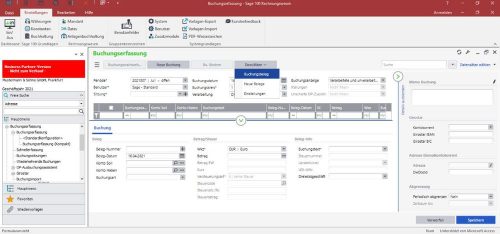

COSYS can connect to ERP systems like SAP, Microsoft Dynamics, Sage, and many others, ensuring smooth data exchange between platforms.

Typical use case: from planning to completion

Let’s walk through a typical stocktake scenario using COSYS:

- Preparation

The inventory manager at HQ schedules the stocktake and sets deadlines. Tasks are assigned to the relevant warehouse or retail locations. - Execution

Local teams receive push notifications and begin scanning items using mobile devices. The software guides them through predefined zones or product categories. - Data Upload

Once the count is complete, results are automatically uploaded to the central system. Any errors or mismatches are flagged for review. - Review & Reporting

Managers review the aggregated results in real time, export reports, and initiate follow-up actions as needed—all from the COSYS WebDesk.

This structured workflow significantly reduces downtime, boosts transparency, and ensures all locations follow the same procedures.

Software + hardware from one source

COSYS also supports your stocktaking with a rental model for mobile devices. Whether you need rugged enterprise scanners like the Zebra TC21/TC26 or Honeywell EDA52, or just want to equip your teams with easy-to-use smartphones, COSYS provides preconfigured hardware for your inventory period—including logistics and technical support.

By combining software and hardware into a unified service, you eliminate the hassle of sourcing, setup, and compatibility issues. It’s a complete, ready-to-use solution that simplifies the entire inventory process.

Conclusion

With the stocktaking software by COSYS, companies can finally take full control of their inventory process—without sacrificing speed, accuracy, or flexibility. Centralized oversight ensures alignment with corporate goals, while local execution ensures responsiveness and efficiency on the ground.

Whether you’re running a single facility or a vast logistics network, COSYS helps you stay in control, reduce errors, and finish your inventory faster.

Ready to simplify your next stocktake?

Contact COSYS today for a free demo or consultation.

COSYS Ident GmbH, based in Grasdorf (near Hildesheim, Germany), has been in existence for almost 40 years and is one of the leading system houses in the field of mobile data capture solutions for Android and Windows. A medium-sized company that has been driving the development of identification systems since 1982 and today offers industry-specific complete solutions for almost all common business processes. From process design and concept development to hardware and software implementation, project management and customized maintenance contracts, we cover the entire range of system development, integration and support services. COSYS also offers a repair service, WLAN radio measurement and solutions for component traceability using DPM codes.

Cosys Ident GmbH

Am Kronsberg 1

31188 Holle – Grasdorf

Telefon: +49 (5062) 900-0

Telefax: +49 (5062) 900-30

http://www.cosys.de

Telefon: +49 (5062) 900-0

E-Mail: vertrieb@cosys.de

![]()