Through thick and thin: EMG iTiM high-precision thickness measurement now part of the EMG portfolio

The expansion of the product portfolio by the thickness measurement – under the product name EMG iTiM – means for the quality management the availability of a wide range of sensor and automation solutions from one source!

EMG iTiM solutions are characterised by the combination respectively use of a wide variety of physical measuring methods, a high degree of flexibility in design and easy integration into the user’s automation environment. The new systems ideally complement the solutions for online oil film thickness measurement already known under the product name EMG SOLID®, which can now also be used for measuring the layer thickness of insulating coatings on electrical sheet.

Technological competence paired with application knowledge

High-precision, fully automatic online thickness measurements require a high degree of technological competence, which must relate to a wide range of applications. Only a precise understanding of the specifics of the application and consideration of the accuracy requirements will result in a customised solution for the individual application. Laser measurement systems, for example, are easy to use and comparatively cost-effective to purchase, but have physical limitations in terms of absolute measurement accuracy. Here the comprehensive solution expertise of the extended EMG team, based on decades of experience, comes into play. This is technologically reflected in the application spectrum of the EMG iTiM sensor family.

The EMG iTiM thickness measurement solutions

EMG iTiM iso

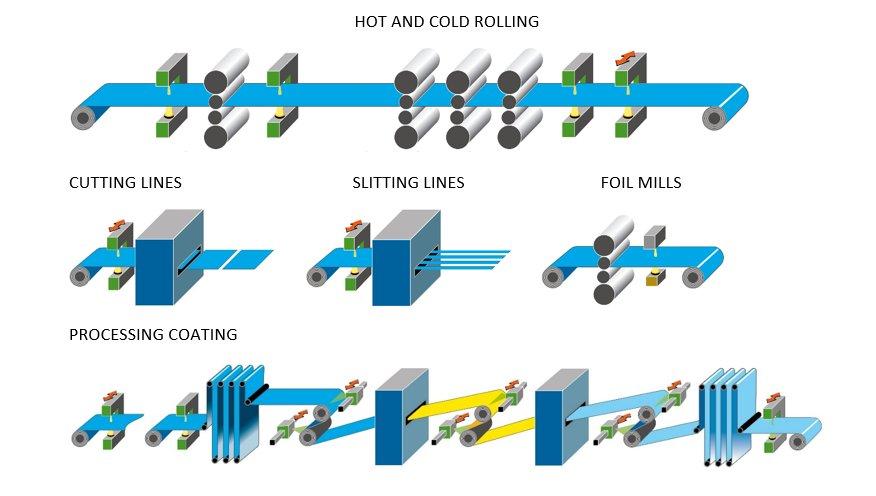

The isotope radiation-based measuring system EMG iTiM iso works with different isotopes depending on the field of application and is used in both hot and cold processes. The flexible system design enables both single-point measurement systems and complex thickness profile measurements.

EMG iTiM xray

EMG iTiM xray uses the high-precision X-ray thickness measurement method. EMG iTiM xray can be used with a wide variety of materials due to the different generator voltages. From wafer-thin foils to thick strips. Here, too, single-point measurements and high-resolution thickness profile measurements are possible.

EMG iTiM laser

The EMG iTiM laser optical thickness measurement systems are characterised by low complexity, compact space requirements and flexible integration into the production line, which represents an economical alternative to more complex and costly system solutions, especially for steel and aluminium service centres and automotive lines.

Field of competence: retrofits and modernisations

The broad availability of a wide range of sensor technologies and EMG’s extensive integration and application know-how enable the customer to realise a very economical and efficient upgrade of existing systems by reusing system components during retrofitting and modernisation.

By expanding the EMG product portfolio of quality assurance systems with the EMG iTiM thickness measurement solutions, the user receives a proven and reliable solution for precise measurement of strip thickness in a wide range of applications. Each installation is configured line-specifically and equipped with the appropriate combination and design of sensors for the specific application. In addition, customers worldwide benefit from EMG’s existing international service network with personal expert advice directly on site.

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Vice President Global Marketing

Telefon: +492762612126

E-Mail: nicol.otterbach@elexis.de

![]()