Canada Nickel and NetCarb Advance Strategic Partnership to Unlock Zero Carbon Industrial Cluster in Northeastern Ontario

- Unlocking additional value from carbon sequestration and mineral by-products from Crawford Nickel Project tailings

- Enabling multiple low-carbon industries: blue-green hydrogen, ammonia, urea fertilizer, and magnesium products

- Supporting Ontario and Eastern Canada’s self-sufficiency in fertilizers and magnesium

- Advancing local clean energy and megatonne carbon removal using regional biomass

Canada Nickel Company Inc. ("Canada Nickel" or the "Company") (TSXV:CNC) (OTCQX:CNIKF) (- https://www.commodity-tv.com/play/analysis-of-the-nickel-market-and-why-canada-nickel-has-great-potential/ – ) is pleased to announce the next phase of its strategic partnership with NetCarb, outlining new product opportunities and a path forward for unlocking the potential for a zero carbon industrial cluster in Northeastern Ontario. This collaboration leverages NetCarb’s advanced carbon sequestration process which can utilize tailings from the Crawford Nickel project and the Company’s other projects across the Timmins Nickel District to capture and store carbon dioxide while producing valuable by-products.

Mark Selby, CEO of Canada Nickel, said, “This next phase of collaboration with NetCarb is a pivotal step forward in our strategic partnership. We have completed an initial assessment of high potential products which leverage the minerals in our tailings, the inherent strengths of Northeast Ontario and each of our proprietary technologies to identify potential anchor industries for a Northeast Ontario zero carbon industrial cluster. As we did with our initial development of our patented IPT Carbonation process, we will rapidly assess the technical and economic viability of each opportunity, leveraging available government funding to take each opportunity through each stage from lab scale to pilot scale to full feasibility. This approach will enable the Company to identify and attract potential partners to advance each of these opportunities as the Company continues to focus on advancing its flagship Crawford project.”

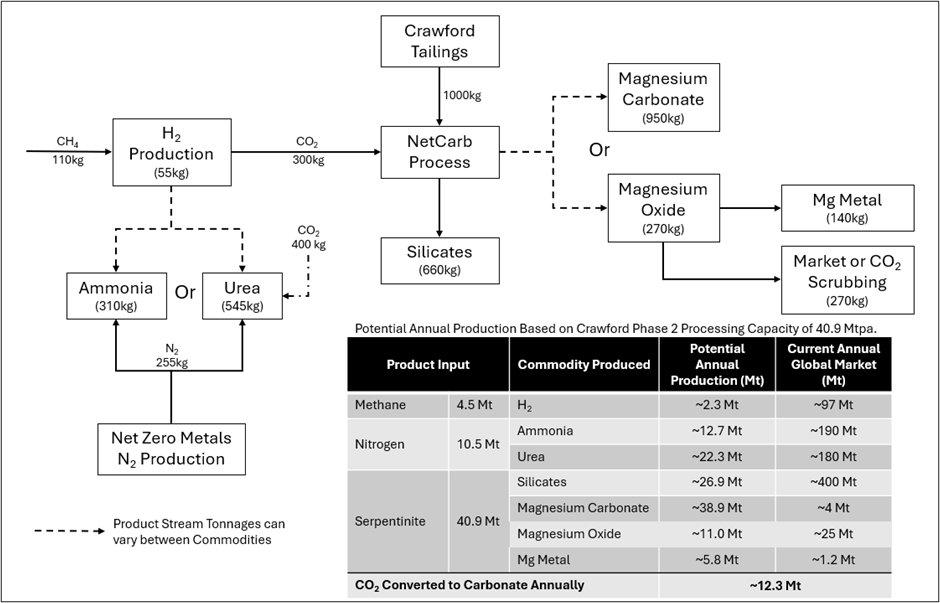

Since announcing a strategic partnership on June 9, 2025, Canada Nickel and NetCarb have made progress in understanding how the NetCarb proprietary carbon sequestration process can create value from Crawford tailings. We believe that this technology has the potential to sequester up to ten times the amount of CO2 that Canada Nickel’s proprietary IPT Carbonation can achieve, while also generating by-products such as hydrogen and magnesium.

Dr. Luke Keeney, Managing Director and CEO of NetCarb said, “NetCarb’s enhanced carbon sequestration technology could significantly extend the value of Canada Nickel’s tailings, positioning the Timmins Nickel District as a leading decarbonisation hub in Eastern Canada and unlocking new industries and economic opportunities for the region.”

Through lab, pilot and engineering activities, Canada Nickel and NetCarb will pursue the demonstration of the cutting-edge process through a rapid development program that focusses on three highly prospective by-product focus areas in addition to utilizing the enhanced carbon sequestration capacity.

Blue-green Hydrogen and hydrogen based products (Ammonia, Urea, Ammonium Nitrate)

The NetCarb process offers the potential to produce a carbon neutral hydrogen product using a steam methane reforming (SMR) process that sequesters the carbon dioxide generated in the tailings. This approach, which combines attributes of both blue and green hydrogen, represents a new category of low-carbon hydrogen production. Hydrogen is a valuable product on its own, however it is also a key ingredient for the production of other materials such as urea or ammonia and valuable products for Ontario:

- Hydrogen has potential as a zero emission fuel that could be supplied to the nearby natural gas pipeline to lower the carbon footprint of the natural gas energy supply. The ability to produce power using a natural gas that contains hydrogen has been the focus of significant research and development through existing government hydrogen innovation funds.

- Ammonia is typically used to make nitrogen-based fertilisers and explosives, it also has a potential application for assisting in the transportation of hydrogen as a fuel. Through further processing, the hydrogen produced from the NetCarb process could be readily converted into ammonia using established industrial processes.

- Urea is a fertilizer used in agriculture to enhance the nitrogen content of soils. It is typically produced from ammonia combined with CO2 and is currently a net import to Eastern Canada. As a potential byproduct of the NetCarb process, urea production could improve regional self-sufficiency in fertilizers.

The joint development program will focus on three main areas: blue-green hydrogen and low-carbon fertilizers, magnesium-based products, and enhanced carbon removal using local biomass. Canada Nickel and NetCarb will continue to advance these initiatives through laboratory, pilot, and engineering phases, with the goal of establishing Northeastern Ontario as a model for zero carbon industrial development.

Given the extensive ultramafic resources in the Timmins Nickel District, there is potential to generate high-value by-products. NetCarb estimates that each tonne of Crawford tailings has the potential to store approximately 300 kg of carbon dioxide while producing 55 kg of hydrogen which could be further utilized to produce 310 kg ammonia or 545 kg of urea.

Magnesium-based products and potential for distributed carbon capture support

In addition to the hydrogen production, NetCarb’s technology generates a magnesium material which can be processed into products such as magnesium carbonate (MgCO3) or magnesium oxide (MgO). The potential to produce MgO, which is a product that is highly reactive with CO2, is particularly exciting as this material could effectively be distributed as a CO2 scrubbing agent to businesses across Eastern Canada. By leveraging the provincial road and rail network, MgO produced from Crawford tailings can be transported and deployed beyond Timmins, extending the reach of the region’s carbon sequestration capabilities. Each tonne of Crawford tailings has the potential to generate 270 kg of low carbon, or carbon neutral MgO utilizing NetCarb’s process.

Local Biomass Energy and Biofuel Production, and Megatonne Carbon Removal

Northeast Ontario possesses significant biomass harvesting capacity, much of which has been underutilized over the last two decades as traditional pulp, paper, and forestry products capacity has been closed. Canada Nickel is already actively exploring the use of local biomass to use as a reductant to decrease the carbon footprint of its downstream processing facilities.

The NetCarb-Canada Nickel partnership has identified opportunities to utilize primary forestry biomass and forestry and agricultural waste to produce biofuels or generate energy. By capturing and sequestering the CO2 generated using Crawford tailings and the NetCarb process, the process has the potential to be net carbon negative and achieve annual megatonne carbon removal while generating byproducts from multiple sources of waste. Figure 2 illustrates the approaches for biofuel and biomass power generation.

What is Blue-Green Hydrogen

Hydrogen is classified by colour, based on the source of the hydrogen and what happens to the carbon dioxide generated. The potential hydrogen by-product from the NetCarb process shares characteristics of both blue and green hydrogens:

- Blue hydrogen is produced from natural gas through steam reforming, where the resulting carbon dioxide (CO2) by-product is captured and stored using carbon capture and storage (CCS) technologies.

- Green hydrogen is produced through electrolysis using renewable energy sources, such as wind or solar power, producing hydrogen without greenhouse gas emissions.

The NetCarb process enables use of lower cost hydrogen production through steam methane reforming, while CO2 emissions are mineralized and sequestered in the tailings residue. This approach results in a carbon-neutral hydrogen product with CO2 permanently stored in a geologically stable mineral form.

NetCarb Proprietary process

Unlike Canada Nickel’s IPT Carbonation process, which focuses solely on brucite, the NetCarb technology targets a more complete carbonation of serpentine minerals. This proprietary process involves serpentinite activation followed by hydrometallurgical processing of ore through a CO2 activity swing reactor that effectively dissolves and re-precipitates magnesium as solid carbonate minerals for permanent carbon dioxide sequestration. We believe that the NetCarb process has the potential to sequester up to ten times the amount of carbon dioxide that can be achieved with IPT Carbonation and represents a significant leap forward in carbon capture technology.

Next Steps

Canada Nickel and NetCarb will be submitting a series of funding proposals to various granting agencies through the balance of 2025 with a view to completing lab scale work on targeted processes during 2026. Successfully developed processes will pave the way for identifying potential strategic partners to support pilot-scale demonstrations in 2027, with the goal of advancing each process toward full commercialization.

Qualified Person

Arthur G. Stokreef, P.Eng (ON), Manager of Process Engineering & Geometallurgy and a "qualified person" as such term is defined by National Instrument 43-101, has reviewed and approved the technical information in this news release on behalf of Canada Nickel Company Inc.

About NetCarb

NetCarb Pty Ltd is accelerating the global shift to a low-carbon economy with advanced technologies that help businesses reduce emissions and meet their net zero commitments. Through cross-industry collaboration, NetCarb supports the scale-up of sustainable solutions, improves operational efficiency, and brings innovative, eco-friendly products to market—aligning environmental responsibility with long term economic value. At the core of NetCarb’s innovation is its breakthrough in carbon mineralisation, a natural process where atmospheric CO₂ reacts with rock to form stable carbonates. While this process typically occurs over geological timescales and removes around 0.3 billion tonnes of CO₂ annually, NetCarb’s technology accelerates it by approximately 100 million times. This advancement enables scalable, permanent carbon storage at economically viable rates, positioning NetCarb as a key player in the multi-gigaton carbon capture market. To learn more, visit https://netcarb.com.au.

About Canada Nickel Company

Canada Nickel Company Inc. is advancing the next generation of nickel-sulphide projects to deliver nickel required to feed the high growth electric vehicle and stainless steel markets. Canada Nickel Company has applied in multiple jurisdictions to trademark the terms NetZero NickelTM, NetZero CobaltTM, NetZero IronTM and is pursuing the development of processes to allow the production of net zero carbon nickel, cobalt, and iron products. Canada Nickel provides investors with leverage to nickel in low political risk jurisdictions. Canada Nickel is currently anchored by its 100% owned flagship Crawford Nickel-Cobalt Sulphide Project in the heart of the prolific Timmins-Cochrane mining camp. For more information, please visit www.canadanickel.com.

Media, please contact:

Sydney Oakes

Director of Indigenous Relations and Public Affairs

sydneyoakes@canadanickel.com

For further information, please contact:

Mark Selby

CEO

Phone: 647-256-1954

Email: info@canadanickel.com

In Europe

Swiss Resource Capital AG

Jochen Staiger & Marc Ollinger

info@resource-capital.ch

www.resource-capital.ch

Cautionary Statement Concerning Forward-Looking Statements

This press release contains certain information that may constitute "forward-looking information" under applicable Canadian securities legislation. Forward looking information includes, but is not limited to, whether the technology has the potential to sequester up to ten times the amount of CO2 that Canada Nickel’s proprietary IPT Carbonation can achieve, while also generating valuable by-products such as hydrogen and magnesium; new product opportunities and a path forward for unlocking the potential for a zero carbon industrial cluster in Northeastern Ontario; the potential to produce a carbon neutral hydrogen product using a steam methane reforming (SMR) process that sequesters the carbon dioxide generated in the tailings; opportunities to utilize primary forestry biomass and forestry and agricultural waste to produce biofuels or generate energy; whether successfully developed processes will pave the way for identifying potential strategic partners to support pilot-scale demonstrations in 2027, and the goal of advancing each process toward full commercialization, whether the process is technically or economically viable and the availability of governing funding. Forward-looking information is necessarily based upon several assumptions that, while considered reasonable, are subject to known and unknown risks, uncertainties, and other factors which may cause the actual results and future events to differ materially from those expressed or implied by such forward-looking information. Factors that could affect the outcome include, among others: future prices and the supply of metals, the future demand for metals, the results of drilling, inability to raise the money necessary to incur the expenditures required to retain and advance the property, environmental liabilities (known and unknown), general business, economic, competitive, political and social uncertainties, results of exploration programs, risks of the mining industry, delays in obtaining governmental approvals, failure to obtain regulatory or shareholder approvals. There can be no assurance that such information will prove to be accurate, as actual results and future events could differ materially from those anticipated in such information. Accordingly, readers should not place undue reliance on forward-looking information. All forward-looking information contained in this press release is given as of the date hereof and is based upon the opinions and estimates of management and information available to management as at the date hereof. Canada Nickel disclaims any intention or obligation to update or revise any forward-looking information, whether because of new information, future events or otherwise, except as required by law.

Swiss Resource Capital AG

Poststrasse 1

CH9100 Herisau

Telefon: +41 (71) 354-8501

Telefax: +41 (71) 560-4271

http://www.resource-capital.ch

CEO

Telefon: +41 (71) 3548501

E-Mail: js@resource-capital.ch

![]()