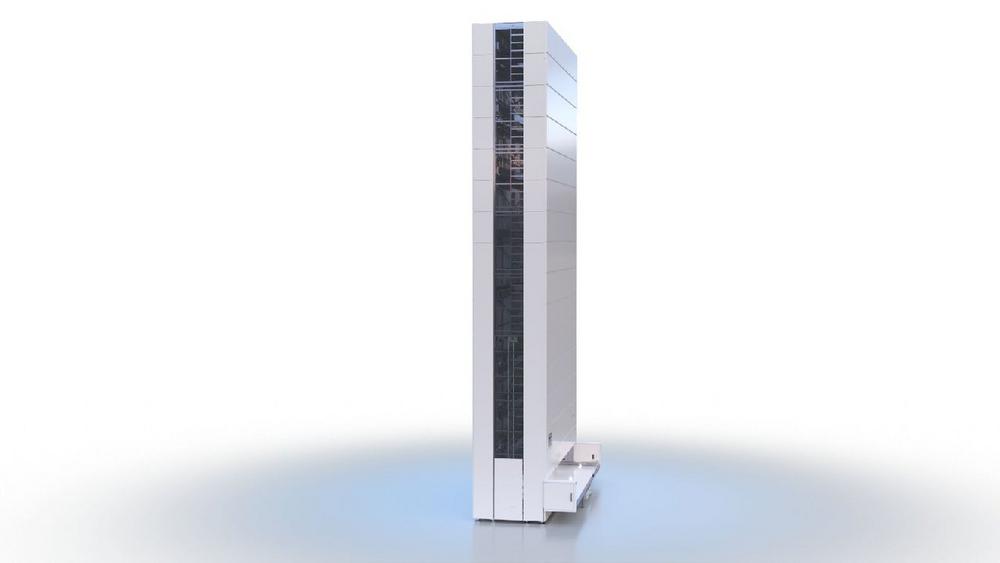

Modula Long Goods extends vertical automation to meet industrial requirements for long material storage

Halle 1 / Stand: 1C67

Meeting the requirements for storing long materials is the objective of Modula Long Goods, the new vertical automated storage system developed by Modula. The system extends vertical automation to the handling of long items. The Italian company will present the new solution at the international exhibithion LogiMAT, where it will exhibit in Hall 1, Stand 1C67.

Modula Long Goods addresses a concrete operational need found in many industrial environments, where the length of materials represents a structural limitation for conventional vertical automated storage systems. The system enables automated storage of long materials up to 7 metres, significantly expanding the application scope of vertical automation within production and logistics facilities and offering a structured alternative to traditional handling methods.

The solution represents a direct evolution of the Modula Lift system. It inherits the same operating principle, goods-to-person logic and modular architecture, applying the proven Lift technology to a new product category. As a result, Modula Long Goods ensures the same standards of reliability, operational safety, ergonomics and warehouse flow efficiency that characterize Modula’s established solutions, while extending their benefits to long and bulky materials.

Modula Long Goods is available in two product versions, designed around different tray depths to meet specific storage requirements. The standard Modula “Long Goods version” features a tray depth of 637 mm with a usable storage width of 7,060 mm. Tray height starts from a minimum of 237 mm and can be configured with height extensions up to 600 mm, ensuring adaptability to different material profiles. The Modula “Long Goods D version” offers an increased tray depth of 840 mm, while maintaining the same usable width and height configurations, providing additional flexibility for applications requiring higher depth capacity.

In both versions, trays can be subdivided along the depth using up to four dividers, enabling the creation of four parallel rows of long materials within the same tray. This configuration improves space utilization, material organization and picking efficiency, while ensuring correct load handling and material stability during storage and retrieval operations.

Modula Long Goods is designed for the storage of aluminum and PVC bars, profiles, extruded parts, and similar long items, which are often managed with floor-based or non-structured solutions requiring large footprints, limited accessibility and offering reduced inventory visibility. The system supports a total net storage capacity of up to 80,000 kg, with up to 900 kg per tray. Configurations can reach heights of up to 24 meters, enabling optimal usage of vertical space and a significant reduction in floor space requirements.

The external bay supports integration with manipulators, overhead cranes and direct forklift access, allowing to load and unload materials directly at the bay. Optional features include a lateral bay opening for side extraction of individual bars—ideal for integration with cutting machines or processing lines—and a fold-down tray option, further improving operational flexibility in highly integrated production environments. Modula Long Goods integrates with the Modula WMS, enabling structured, digital and fully traceable management of long materials and supporting integration with existing ERP systems.

For more information: www.modula.eu

Modula SpA

Via San Lorenzo 41

I42013 Salvaterra di Casalgrande

Telefon: +39 (0522) 774111

http://www.modula.com

Marketing & Communications Specialist

Telefon: 39 0522 774111

E-Mail: Francesca.Benassi@modula.com

![]()