-

Proven and variable

With the MCA power clamping nut from JAKOB Antriebstechnik, the user has at his disposal a long-proven, widely used and economical clamping element. Without additional installation effort, this clamping technology can ensure the highest clamping forces and maximum operational reliability – and is easy to operate manually. For this only a wrench SW 17 is required. Nevertheless, it is recommended to use a torque wrench to set exact, reproducible tightening torques. The special inner life, an integrated planetary gear mechanics, multiplies the manual tightening torque. Their durability has been proven on a specially designed test bench. They were subjected to a continuous load of 10,000 load changes and were able…

-

Power clamping screw MSPD – Under pressure

Workpieces measuring up to approximately 50cm are typically clamped manually and mechanically using three- or four-jaw chucks, or automatically through pneumatic or hydraulic means. However, when dealing with larger workpieces, planar disks come into play. These disks securely hold much larger parts in place using jaw boxes and tensioning spindles. Users can select from 7 standard thread sizes ranging from TR 50 to TR 200, allowing clamping forces of up to 500 kN to be achieved thanks to the proven wedge clamping system, ensuring self-locking in each clamping position and a high level of stiffness. Equipped with an internal switchover for external and internal clamping, the MSP/MSPD power clamping spindles…

-

High-Speed with KG-HS

With the KG-HS coupling series, JAKOB Antriebstechnik offers a high-speed version of the popular KG metal bellows coupling. It is manufactured with clamping hubs in a splitted hub design on both sides. Assembly and disassembly are no longer difficult, even in cramped installation conditions. The rotationally symmetrical clamping hub ensures optimum balancing quality, the secure connection between the bellows and the hub is guaranteed with the micro-plasma welding process. The new series offers nominal torques of 5-1000 Nm at a temperature range of -40°C to 350°C. Firmenkontakt und Herausgeber der Meldung: JAKOB Antriebstechnik GmbH Daimlerring 42 63839 Kleinwallstadt Telefon: +49 (6022) 22080 Telefax: +49 (6022) 220822 https://jakobantriebstechnik.de/ Ansprechpartner: Jan Möller…

-

Popular series more variable KG-VA, KGH und KGE

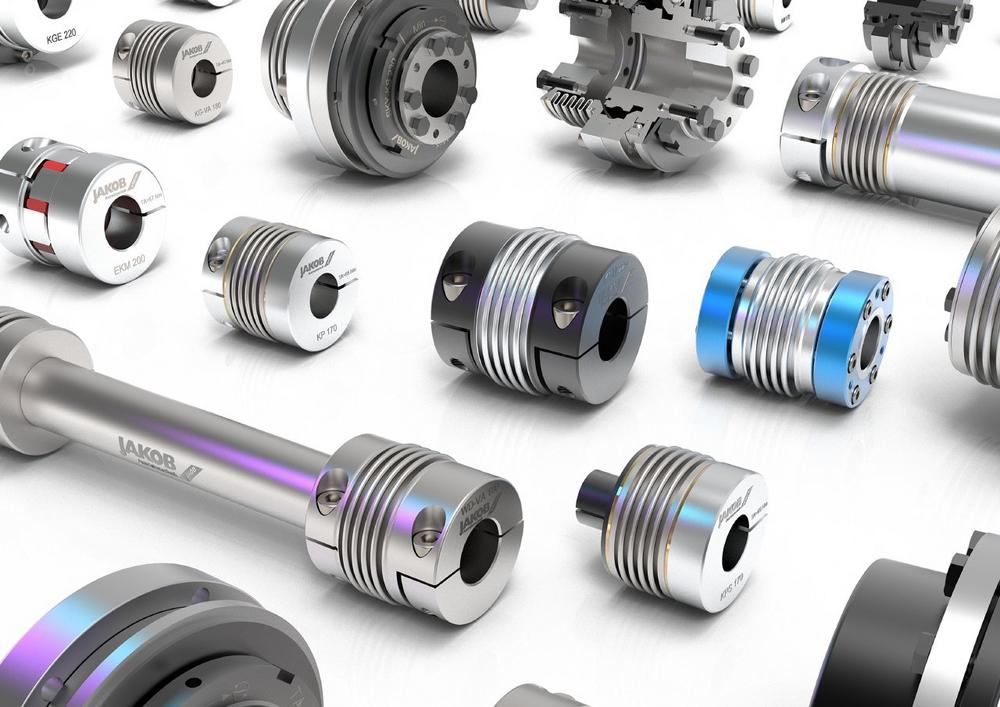

The versatile metal bellows couplings of the KG-VA, KGH and KGE series from JAKOB Antriebstechnik have been expanded. They were previously available in 2 and 4 corrugated versions; the 6 corrugated bellows have been added. This means that the series can be used even more flexibly, longer shaft distances can be bridged and larger offsets can be compensated. In addition to these series, the company also offers many other standard series or custom-made products. The KG-VA series The KG-VA series in stainless steel meets high requirements. The couplings are available for torque ranges from 30 – 1000 Nm and shaft diameters from 10 – 90 mm. It can be used…

-

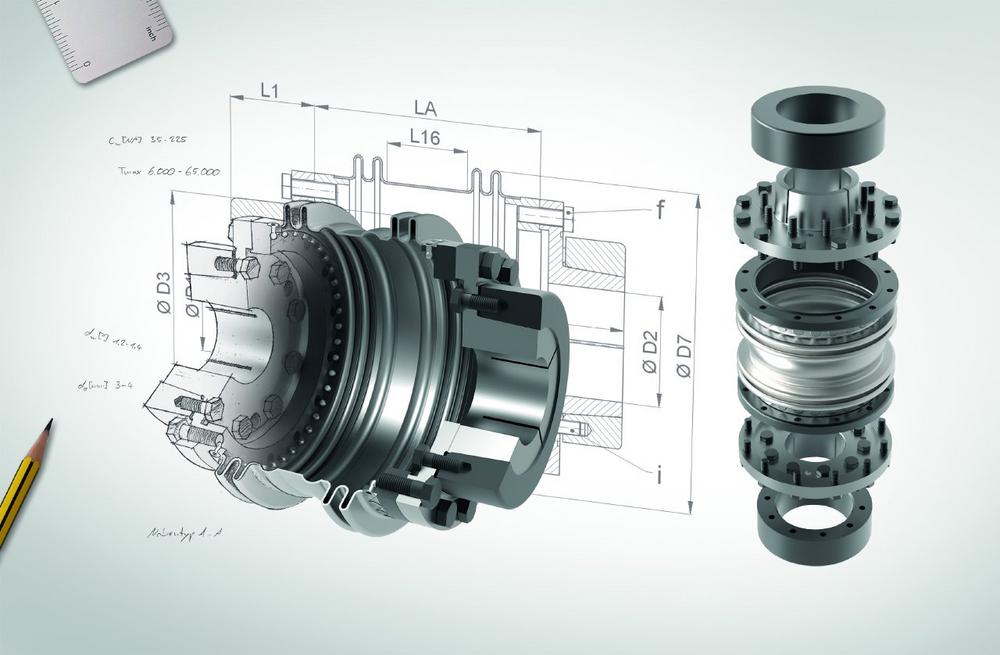

Metal bellows coupling KXL – For big achievements

Safe and accurate transmission of torques is essential for precision drives of cross cutters. This is ensured by the use of steel bellows couplings with force-fitted shaft-hub connection. The metal bellows couplings of the KXL series from JAKOB Antriebstechnik GmbH were designed for medium and large drives up to a maximum of 65,000 Nm. A special design feature is the three-piece design with a flexible bellows package as an intermediate piece. This removable intermediate piece, consisting of an optimized, torsionally stiff stainless steel bellows with 2 bellows shafts per side and a variable length intermediate pipe, is frictionally connected (screws ISO 4017 / 10.9) with the two hubs. This results…

-

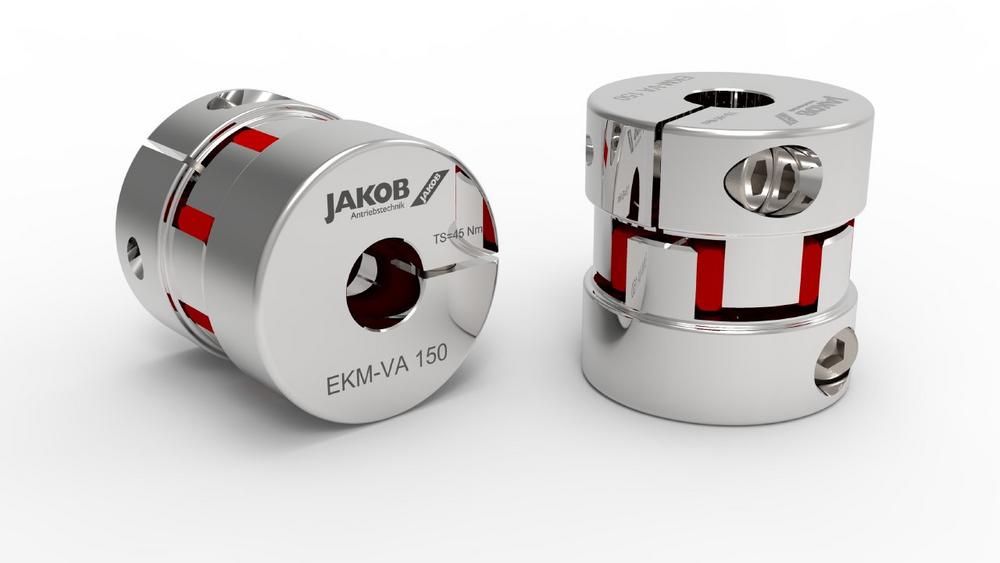

Resistant – Elastomer coupling EKM-VA

Jakob’s product range of elastomer couplings has been expanded to include a new variant, the EKM-VA. This stainless steel variant of the proven EKM coupling is particularly characterized by its resistance to chemicals, which makes it particularly suitable for applications in the food industry, for example in cleaning processes. The elastomer couplings are pluggable, backlash-free and flexible shaft couplings that are designed for small and medium torques of up to 2000 Nm. They consist of a plastic star with involute-shaped teeth and high Shore hardness as a connecting and compensating element. This star is inserted positively and slightly pre-tensioned into two highly precisely manufactured hubs with claw-shaped cams. The elastic…

-

SKB-KP – Torque limiter for direct drives expanded

The tried-and-tested SKB-KP series safety coupling has been used for decades to provide mechanical protection for drive units. It has already proven its effectiveness in hundreds of applications, especially when used as collision protection in the feed axes of machine tools. As a combination of a metal bellows servo coupling and the unique JAKOB safety mechanism, the SKB-KP series is flexible, free of play, compensates for misalignment, has a low moment of inertia and high torsional stiffness. In this way, precise transmission of the torque can be guaranteed. By using clamping sets, the torque setting range could again be significantly increased, so clamping forces of up to 9000 Nm can…

-

Dependable and affordable

Over decades in the market, it has proven itself to be a reliable and cost-effective standard series among metal bellows couplings: the KM metal bellows coupling by JAKOB Antriebstechnik. Like all metal bellows couplings, it is rigid in rotational direction but flexible in axial, angular, and radial directions. Despite the similarities, metal bellows couplings can vary significantly from each other. The technical differences lie, for example, in the choice of bellows or the connection method between bellows and hub or bellows and shaft. JAKOB utilizes only thin-walled, multi-layer bellows made from certified stainless steel sheets. This results in high torsional stiffness, ensuring precise positioning and concentricity even under challenging conditions,…

-

Zuverlässig und kostengünstig

Seit Jahrzehnten hat sie sich auf dem Markt als zuverlässige und kostengünstige Standardreihe unter den Metallbalgkupplungen bewährt: die Metallbalgkupplung KM von JAKOB Antriebstechnik. Wie alle Metallbalgkupplungen ist sie in Drehrichtung steif, aber in axialer, winkeliger und radialer Richtung flexibel. Trotz der Ähnlichkeiten können sich Metallbalgkupplungen stark voneinander unterscheiden. Die technischen Unterschiede liegen zum Beispiel in der Wahl des Balges oder der Verbindungsart von Balg und Nabe oder Balg und Welle. JAKOB verwendet ausschließlich dünnwandige, mehrlagige Bälge aus zertifizierten Edelstahlblechen. Dies gewährleistet eine hohe Drehfedersteifigkeit, die eine präzise Positionierung und Rundlaufgenauigkeit auch unter anspruchsvollen Bedingungen sicherstellt und eine absolut spielfreie Drehmomentübertragung zwischen An- und Abtriebswelle garantiert. Die mehrlagige Bauweise des Balges…

-

How to choose a suitable servo clutch

In order to choose a suitable clutch for the drive train, various factors must be taken into account. Particular attention is paid to the required torque range, offset and ambient temperatures of the coupling. First, the maximum required torque is determined. The coupling should be selected accordingly, whereby long-term use in overload or absolute limit ranges should be avoided. Misalignment plays a critical role in clutch life. Precise alignment is therefore essential as greater misalignment reduces the life expectancy of the coupling. The compensable lateral offset usually varies between 0.15 and 0.3 mm and is highly dependent on the number of bellows shafts. For example, a 4-shaft coupling has significantly…