Company-wide availability of engineering data

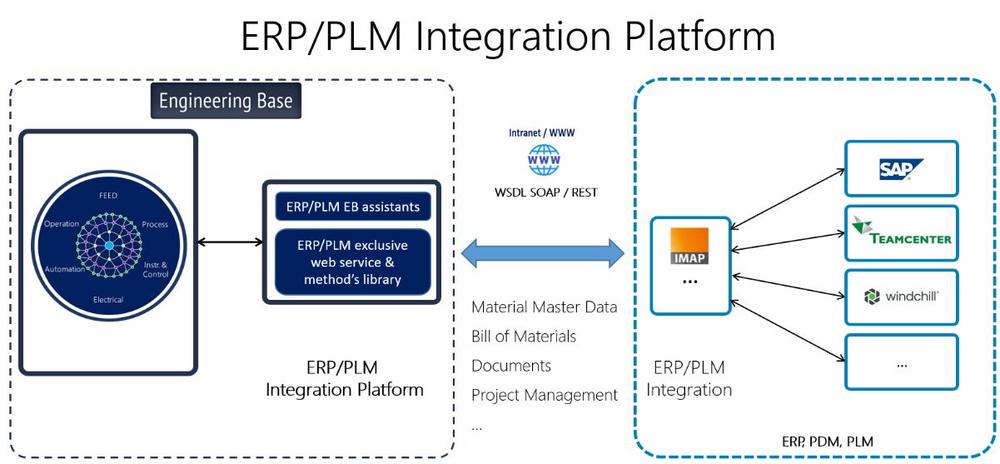

The software system company Aucotec has developed a new, standardized interface to ERP and PLM systems for its object-oriented cooperation platform Engineering Base (EB). It shortens the integration time as well as the subsequent data exchange.

Seamless from material master to project management?

Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM) are an essential part of modern corporate management and administration. The larger the company and the more complex its products, the more complex the tasks and processes are in ERP. The relevant systems are equipped with numerous tools for various application areas. This set-up requires experienced experts.

Engineering also has its specialists who know "their" systems like the back of their hand. To ensure optimal process reliability and data consistency, ERP and engineering must work seamlessly together. Regardless of whether material master, BOM, document, or project management: both areas are always involved and must be able to rely on up-to-date data. However, data transfers, duplicate data maintenance and the expertise that is often required with respect to a system outside one’s own area of expertise are significant hurdles that have to be cleared.

Standard for the exchange of expertise

Aucotec developed the ERP/PLM integration platform for EB in order to significantly simplify the exchange of knowledge with optimum data quality. It does not require any special ERP/PLM expertise from the engineering user. While the platform can be "docked" to any company’s own middleware, it also offers all-round standardized integration for SAP, Windchill and TeamCenter in cooperation with the ERP experts from Aucotec’s partner it-motive and their data hub imap. The interface always remains the same on the EB side, regardless of which ERP system is connected. This significantly reduces the necessary integration and maintenance effort: from set-up via implementation to configuration, it saves around half of the usual time for ERP integration projects.

Web service included

From material master to project management, absolute consistency is ensured for the configurable, regular bidirectional data exchange – without multiple entries and update effort. The ERP/PLM integration platform works in a service-oriented manner. All communication between systems can be done in the background via web services, as EB does not have to be started separately at the workstation. This enables the definition of time-based automatic processes which always ensure up-to-date data in ERP/PLM and engineering. The entire exchange process can also be controlled with EB’s Workflow Assistant, thus ensuring that nothing can be forgotten or overlooked.

Aucotec AG has over 35 years of experience in developing engineering software for the entire lifecycle of machines, plants and mobile systems. The solutions range from flow diagrams via I&C and electrical engineering for large-scale plants to modular harness design in the automotive industry. Aucotec software is in use all over the world. In addition to its headquarters in Hanover, Aucotec operates six further sites in Germany as well as subsidiaries in China, South Korea, France, the United Kingdom, Italy, Austria, Poland, Sweden, Norway and the US. A global network of partners ensures local support throughout the world.

AUCOTEC AG – EN

Hannoversche Straße 105

30916 Isernhagen

Telefon: +49 (511) 6103-0

Telefax: +49 (511) 614074

http://www.aucotec.com

Presse & Öffentlichkeitsarbeit

Telefon: +49 (511) 6103-186

Fax: +49 (511) 614074

E-Mail: jki@aucotec.com

![]()